Managing a supply chain often feels harder than it should be. Teams face delays from miscommunication, struggle with limited visibility, and waste time chasing down updates across multiple systems.

These supply chain collaboration challenges slow down decision-making, create costly mistakes, and make it harder to keep up with customer demand. The good news is that modern platforms can help solve these issues

In this article, we’ll look at seven supply chain collaboration tools designed to help teams improve efficiency, strengthen supplier relationships, and reduce risks.

What Is Supply Chain Collaboration?

Supply chain collaboration is all about different teams and partners working together across the entire supply chain.

Engineers, designers, manufacturers, and suppliers use internal collaboration tools to stay connected.

When everyone has easy data access and seamless communication, it becomes much simpler to keep projects on track.

Teams can link their existing systems through seamless integration, which helps them collaborate effectively, solve CAD issues, avoid delays, and maintain smooth operations.

Types of Supply Chain Collaboration

Here are the main types of collaboration you’ll see in this setting:

- Horizontal collaboration: Companies at the same level, like manufacturers or retailers, share designs and resources to cut costs or reach new markets.

- Vertical collaboration: Suppliers and engineers work side by side, often through CAD tools or design review software, to plan supplier capacity, review 3D models, improve transparency, and deliver more value to customers.

- Cross-functional collaboration: Different departments inside one company, such as design, procurement, production, and logistics, work together on a centralized platform.

7 Best Supply Chain Collaboration Tools in 2025

Supplier collaboration tools are software systems that help companies and their partners work together more closely across the supply chain.

They allow teams to share information in real time, making it easier to manage production schedules, order status, and upcoming demand.

With everyone connected through a collaboration platform, communication becomes faster and more transparent.

Let’s talk about the best supply chain collaboration tools you can use today.

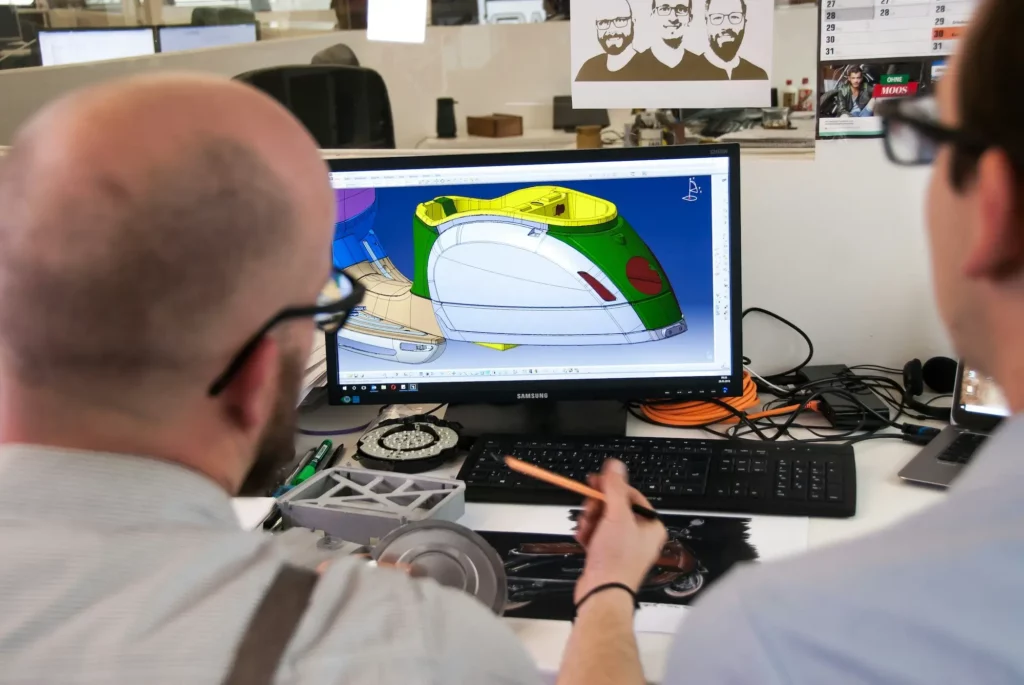

1. CADchat for Seamless Supplier Communication

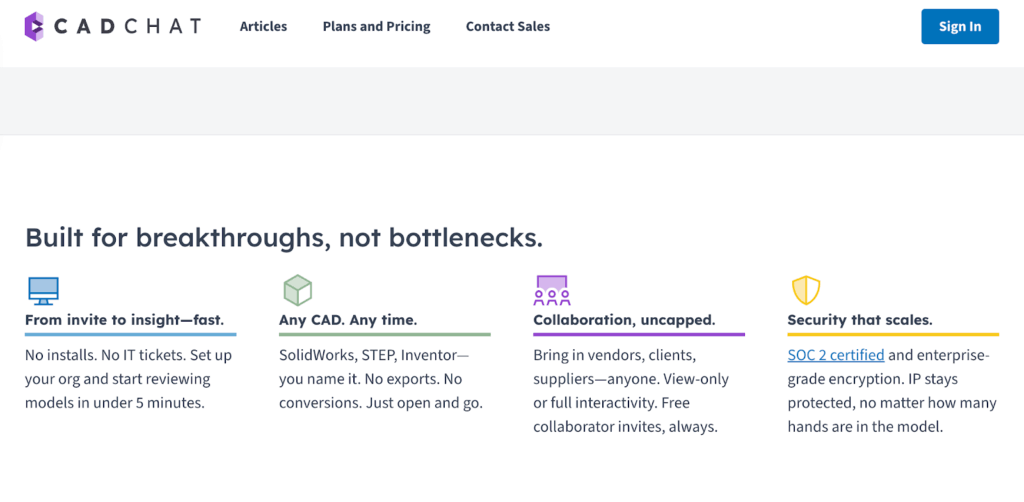

CADchat is a remote collaboration tool that gives teams and suppliers a shared space to work directly on CAD models without confusion or delays.

Instead of juggling emails or static files, external suppliers and logistics providers can collaborate in a dedicated communication channel along with engineers and designers.

This seamless coordination between internal and external partners improves data sharing, speeds up decision-making, and helps keep stock levels visible across the entire process.

Key Features

- Real-time supplier reviews: Collaborate directly on CAD models with suppliers and logistics providers to solve manufacturability issues early

- Asynchronous supplier collaboration: Share feedback anytime, keeping work moving forward across time zones

- Persistent supplier workspaces: Store comments, updates, and approvals with the model, making supplier performance easy to track

- Risk reduction: Use shared data and seamless coordination with suppliers to mitigate risks before they become costly problems

- Faster decision making: Bring all teams into one platform, so engineers, suppliers, and stakeholders can agree on next steps quickly

Get started now and make product reviews with suppliers faster, clearer, and more collaborative.

2. SAP for Supply Chain Management

Source: sap.com

SAP supply chain management software connects supply chain planning, procurement, manufacturing, logistics, and asset management into one system.

With embedded AI and advanced analytics, businesses can use real-time data to predict risks, adapt to volatility, and make informed decisions.

The software also supports digital procurement and includes a supplier collaboration portal, helping teams improve supplier relationships, track performance, and manage sourcing with greater transparency.

Key Features

- Supply chain planning – Tools for forecasting, scenario planning, and aligning production with demand

- Digital procurement – Capabilities for sourcing, contract management, and supplier collaboration through a supplier collaboration portal

- Product lifecycle management – Integration of design, development, and compliance across the product lifecycle

- Supply chain logistics – Features for transportation, inventory tracking, and logistics coordination supported by advanced analytics

- Enterprise asset management – Support for monitoring, maintaining, and optimizing assets throughout the supply chain

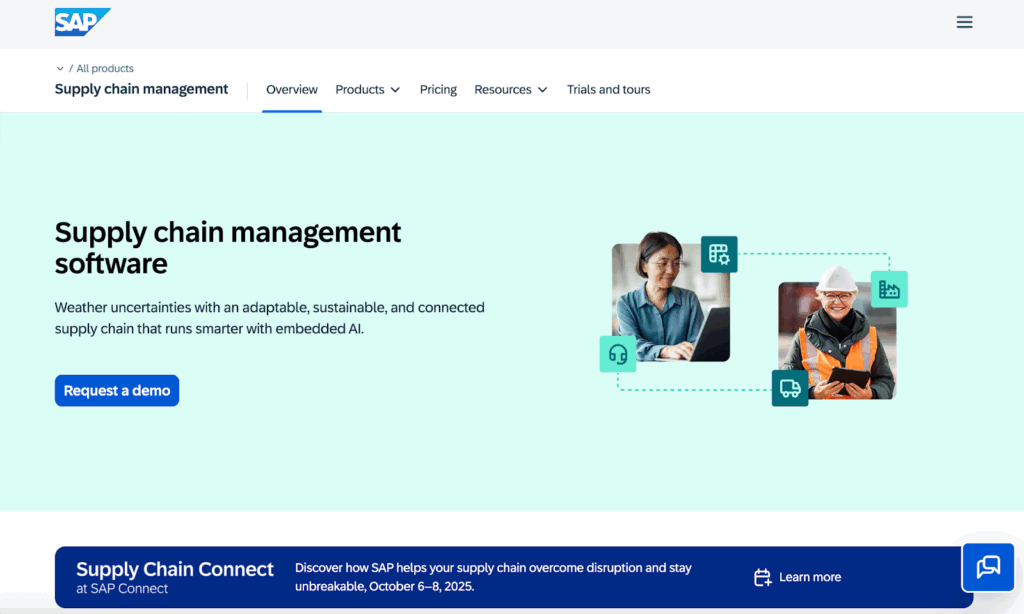

3. Netstock for Supply and Demand Planning

Source: netstock.com

Netstock is a supply and demand planning tool that helps improve how supply chains run.

The platform uses AI-driven insights to forecast demand, optimize inventory levels, and reduce excess inventory.

Analyzing supply and demand patterns provides clear recommendations that help businesses manage delivery schedules, strengthen supplier performance, and maintain balanced stock.

Key Features

- Inventory optimization – Tools to balance inventory levels, reduce excess inventory, and improve cash flow

- Demand planning – AI-driven forecasting to predict demand accurately and support reliable delivery schedules

- Supplier performance – Features to evaluate supplier reliability and impact on overall supply chain performance

- Capacity planning – Support for aligning production and resources with demand in complex supply chains

- ERP integrations – Connections with leading ERP systems to enhance inventory management and provide actionable insights

4. Blue Yonder for AI Demand Forecasting

Source: blueyonder.com

Blue Yonder offers demand forecasting tools that apply artificial intelligence and machine learning to improve planning across supply chains.

The platform generates billions of predictions each day, giving companies a clearer view of how demand will shift under different conditions.

The system also supports approaches where suppliers take a more active role in managing stock, creating more coordinated and responsive supply chains.

Key Features

- AI-driven forecasting – Produces predictions at scale to improve demand accuracy and agility in changing markets

- Data sharing – Provides a shared platform for internal teams and partners to view and update planning data

- Collaborative planning – Encourages joint planning and alignment across suppliers, partners, and different functions

- Inventory coordination – Supports practices that allow closer management of stock levels to reduce shortages and overages

- Integrated platform – Combines supplier forecasting, planning, and execution in a connected system for greater visibility and control

5. Teamwork.com for Task Tracking

Source: teamwork.com

Teamwork.com is project and resource management software designed to help organizations manage client work while also improving task tracking across teams. While not a dedicated supply chain collaboration tool, its features can support supply chain teamwork.

The platform centralizes project details, relevant data, and communication, so tasks are easier to assign, track, and complete.

Teamwork.com can be used by agencies, IT services, consulting firms, and contract manufacturers to coordinate work in one place.

Key Features

- Task tracking – Assign, prioritize, and monitor tasks with clear visibility across projects

- Resource management – View team capacity, balance workloads, and plan ahead with forecasting tools

- Time and billing – Track billable hours and budgets to measure profitability

- Reporting and dashboards – Access relevant data in customizable reports for better oversight

- Integrations – Connect with existing tools and platforms to create smoother workflows

6. Elemica for End-to-End Supply Chain Visibility

Source: elemica.com

Elemica provides network-enabled solutions designed to improve visibility and coordination across complex supply chains.

The platform functions as supply chain collaboration software, connecting manufacturers, suppliers, logistics providers, and distributors into a single digital network.

With tools for order management, invoice handling, quality assurance, and logistics execution, Elemica helps companies monitor transactions in real time and maintain stronger connections with supply chain partners.

Key Features

- Order management and collaboration – Centralized tools for processing and coordinating orders across supply chain partners

- Invoice management – Digital invoice handling with automation, compliance, and archiving capabilities

- Logistics and transportation – Support for multi-carrier shipping execution and shipment tracking

- Quality assurance – Tools to exchange and manage quality documents between manufacturers and suppliers

- Reporting and analytics – Insights into supply chain activity to improve decision-making and operational performance

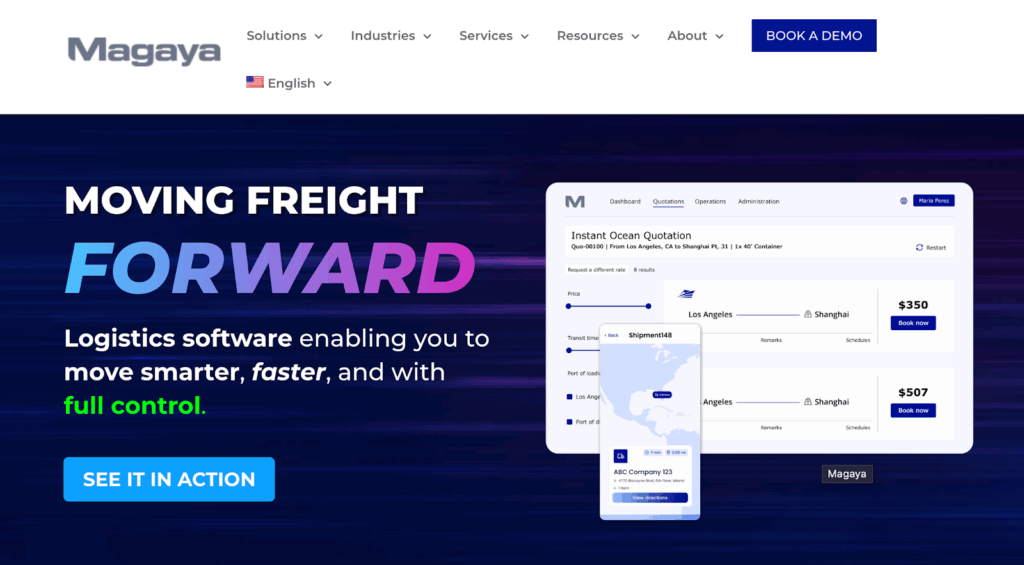

7. Magaya for Freight Forwarding

Source: magaya.com

Magaya is a logistics software platform designed to support freight forwarders and logistics service providers.

It offers tools that help manage procurement efficiency, supplier readiness, rate management, customs compliance, warehousing, and digital freight processes.

The platform enables real-time coordination between internal teams, suppliers, and customers while providing both mobile and web access for end-to-end process management.

Key Features

- Freight rate management – Provides a centralized system for comparing carrier rates, filing tariffs, and preparing quotes to improve procurement efficiency

- Supplier collaboration tools – Supports supplier readiness through integrated communication and data sharing for faster response to market changes

- Customs compliance – Automates filings and documentation to help reduce errors and keep shipments aligned with international regulations

- Warehouse and inventory visibility – Tracks inventory levels and warehouse activity in real time for better control of supply chain operations

- Digital freight portal – Offers self-service options for customers and trading partners to access shipment details, documents, and updates in one place

See how engineers, designers, and suppliers can align in real time. Book your CADchat demo today.

Benefits of Better Supply Chain Collaboration

For product teams, effective collaboration across the supply chain means having the right information at the right time, keeping production lines moving, and making smarter choices with suppliers and trading partners.

Here’s how better supplier collaboration makes a difference.

Cost Reduction and Efficiency

Budgets are always tight, and no team wants surprise costs creeping in mid-project.

By involving suppliers early, product teams can negotiate better deals on materials, sync up delivery schedules, avoid supply chain disruptions, and cut waste in logistics.

These steps help reduce costs and improve supply chain efficiency, giving teams more room to invest in product improvements instead of firefighting expenses later.

Improved Product Quality

Nothing slows a launch like quality issues. Bringing strategic suppliers into the design phase gives product teams valuable insights into materials and manufacturability.

For example, a supplier might suggest a component that’s easier to source and is more reliable, which helps avoid defects once production starts.

Inventory collaboration also makes sure only approved materials reach the line, reducing rework and customer complaints.

Contact our team now and learn how CADchat turns supplier feedback into clear action items.

Greater Supply Chain Resilience

Unplanned events such as port delays or material shortages can stall progress. Teams that collaborate closely with suppliers and logistics providers can identify potential supply chain risks earlier and improve operational efficiency.

For instance, if a shipment is flagged as late, production schedules can be adjusted before the line stops. This proactive approach makes teams more resilient to supply chain disruptions.

Increased Innovation

Collaboration creates space for new ideas. Suppliers often have insights into emerging materials, production techniques, or sustainable alternatives.

By working together, product teams can explore lighter designs, greener materials, or faster processes that provide a real strategic advantage in competitive markets.

Efficiency and Performance

Clear communication and access to relevant data keep product teams focused on delivery instead of admin tasks.

Shared systems with suppliers provide visibility into inventory levels, delivery schedules, and supply planning.

With everyone working from the same information, teams can resolve issues faster and improve overall supply chain efficiency.

Responsiveness to Customer Needs

When customer demand changes, collaboration processes make it easier to adjust production.

Forecast collaboration with trading partners allows teams to prepare ahead of time for seasonal peaks or unexpected shifts.

This helps avoid stock-outs, minimizes excess inventory, and improves customer satisfaction.

Long-Term Strategic Benefits

Strong partnerships with strategic suppliers provide stability, trust, and a foundation that product teams can rely on over time.

These relationships go beyond short-term transactions and create a sense of partnership where both sides share goals and information openly.

During times of shortage or high demand, suppliers are far more likely to prioritize long-term partners who have demonstrated consistent collaboration and reliability.

Collaborate with Suppliers the Easy Way with CADchat

CADchat provides a unified platform where product teams and suppliers can meet, conduct design review meetings, and share feedback in one space.

As supplier collaboration software, it keeps design files current, feedback organized, and decisions easy to track, helping teams improve efficiency and avoid delays.

- Simple to use – No complex setup is required. Suppliers and teams can join a session through a shared link and begin working directly in the CAD model. This straightforward access makes it easy for everyone, even non-technical stakeholders, to participate.

- Work in real time or anytime – Suppliers can join live reviews to check manufacturability or address production details. When schedules differ, they can leave comments directly on the model, making sure collaboration continues without interruption.

- Keep everything in one place – Feedback, files, and design approvals stay attached to the CAD model inside persistent digital workspaces.

FAQs About Supply Chain Collaboration Tools

What is an example of a supply chain collaboration?

A simple example of supply chain collaboration is when a supplier and retailer work closely to share sales data and forecast demand. This can include vendor-managed inventory, where the supplier tracks stock levels and replenishes products without the retailer having to place frequent orders.

What are the 7 C’s of supply chain management?

The 7 C’s of supply chain management are customer, cost, capacity, collaboration, communication, competence, and cash flow. These cover everything from meeting customer needs to managing money and working together across the supply chain.

What are the 4 C’s of SCM?

The 4 C’s of SCM are coordination, cooperation, collaboration, and communication. These highlight the need for businesses to work together and share information so the supply chain runs smoothly and efficiently.

What is CPFR in the supply chain?

CPFR stands for Collaborative Planning, Forecasting, and Replenishment. It’s a process where trading partners share plans, sales data, and forecasts to make sure products are available at the right time while reducing waste and extra costs.