Working with computer-aided design (CAD) files can get messy fast. One team member forgets to label a layer. Another copies old blocks instead of using updated ones. Files grow too big, slow down, or get saved in the wrong version.

And when changes aren’t clear, your team wastes time redoing work or guessing what to fix. These small problems add up and can delay projects, cause confusion, or lead to errors in the final product.

Whether you’re an engineer, designer, manufacturer, or part of a product team, you’ve likely run into these issues. The good news is that many of them can be avoided with a few simple habits.

In this article, we’ll walk through seven easy CAD best practices. These tips will help you save time, reduce mistakes, and keep your projects on track, from the first sketch to the final review.

TL;DR

- Use drawing templates with set CAD standards so every file starts the same way.

- Clean and back up CAD files often so they stay light and you avoid data loss.

- Use blocks and Xrefs to reuse parts and keep drawings linked.

- Keep a simple naming and folder system so everyone can find the right version fast.

- Set up designs in full scale with snaps and grids on for accurate work.

- Lock finished layers so nobody moves completed areas by mistake.

- Leave notes inside drawings so feedback stays clear throughout the whole design process.

- CADchat ties reviews, versions, and comments to the model in one shared space, so your team can agree faster and keep projects moving.

1. Use Drawing Templates With Set CAD Standards

One of the best ways to start any CAD design project is by using a template that already follows your team’s standards.

A good template includes the right layers, fonts, line colors, title blocks, and drawing scales. You can also add notes that match industry standards like AIA or CSI, so outside partners can read your CAD drawings the same way your team does.

Templates support precision drafting. For example, if a designer creates a drawing from scratch and picks the wrong line thickness or text style, it can lead to confusion or project delays.

But with a set template, you can lock in a style for reference dimensions and snaps. That keeps the focus on the actual design instead of small setup tasks.

Using a standard template also helps when working with constraints. Since the structure is already defined, designers can spend more time working with the actual design capabilities of the software instead of fixing formatting issues.

Some teams further create templates that follow ISO standards, such as ISO 128 for drawing layout and ISO 129 for dimension rules, so any part manufactured in one country can be correctly interpreted and reproduced elsewhere.

From first draft to final approval, make every CAD review count. Try CADchat today!

2. Clean Up and Back Up Your CAD Files Regularly

CAD files can get messy over time. Unused layers, blocks, or extra objects can pile up and slow everything down. That’s why regular file maintenance is so important.

Keep your files easy to work with by using tools like purge and audit to clean out things you no longer need. This step keeps CAD models lighter and helps them open and run without lag.

Backing up your work is just as important. CAD design can be time-consuming, and one crash or mistake could lead to major data loss.

Regular backups can save you from redoing hours of work. Use cloud storage or an external drive to make sure your files are safe. If your team manages many revisions, product data management (PDM) software can track versions and record design changes in one place.

Keeping your files clean also makes it easier to track revisions and document changes. When a file is organized, it’s easier to see what’s been added, changed, or removed.

3. Use Blocks and Xrefs to Save Time

When working on CAD design, you often use the same shapes or elements more than once. Instead of redrawing them each time, turn them into blocks.

Blocks make it easy to use the same component in many places. When you change one, all matching blocks update at once. It saves time, cuts down on repetitive tasks, and keeps your technical drawings clean.

Many CAD tools even let blocks hold labels or size options, so you can reuse a part and still match the job.

For larger sections like floor plans or site layouts, it’s better to use external references, also called Xrefs.

Rather than copying big parts into your file, link to them instead. When the source file updates, every linked sheet updates too, so the CAD workflow stays steady.

Using blocks and Xrefs also helps your team work better together. Multiple designers can work on different files at the same time by using shared resources.

And if your company starts using new technologies like shared libraries or file management tools, blocks and Xrefs will work well with those systems.

4. Have a Clear & Organized File Management System

A well-organized file is like a clean toolbox. You can find what you need, understand it, and get back to work without delays because every project follows the same file structure.

Start by using simple names for your files, layers, and blocks. This helps everyone on the team know exactly what they’re looking at and makes it easier to manage CAD files across shared drives.

If a layer is for walls, name it “walls,” not something random or hard to understand. Clear names help people find the right material faster, and they also help optimize workflows when teams hand work off between roles.

It’s also important to properly document your work. Add short notes or comments as you develop the design so the reason behind changes stays clear.

When someone opens the file later, they can quickly see what was done and why. That helps avoid mistakes and speeds up teamwork, especially when files move into manufacturing processes.

Improve communication during CAD model reviews and save time. Start with CADchat.

5. Focus on Accurate CAD Design Setup

A strong CAD design starts with the right setup. One of the most essential steps is to draw everything in full scale. You only apply the scale when it’s time to print.

This helps you keep your work accurate and easy to measure. It also makes it easier for engineers and other team members to review your drawings without confusion.

Turn on object snaps and grid settings at the start. These small tools help you keep lines straight and objects aligned.

They reduce mistakes and help you achieve clean results every time. When your drawing is neat and accurate, it’s easier to do a proper analysis later in the project.

If you skip these setup steps, you might run into constraints that slow down your work. For example, misaligned parts can cause problems when creating sections or dimensions. Fixing them later can be frustrating and time-consuming.

6. Lock Finished Layers

Leaving all layers open can easily introduce errors. A small drag or click can shift a line or block without you noticing.

So, after you finish working on a part of your CAD drawing, it’s always a good idea to lock that layer. This simple step keeps it safe from accidental changes. When layers stay untouched, your drawing stays neat and easy to work with.

Locking also helps during reviews or when making last-minute edits. You won’t move or delete something by mistake.

It also enables better teamwork. When everyone knows which layers are done and protected, they can focus on the active parts of the design. This helps keep the file organized and reduces confusion.

7. Communicate With Your Team Inside the Drawing

One of the easiest ways to work better as a team is to communicate right inside the CAD drawing. Use text notes, comments, or labeled layers to mark what’s finished, what needs review, or where you have questions.

Clear in-drawing notes also help with teamwork. When someone opens the file, they can quickly see what’s going on. It saves time and avoids confusion.

You can also add notes to explain design choices or flag areas that need attention. This helps people understand your work and reduces the chance of mistakes.

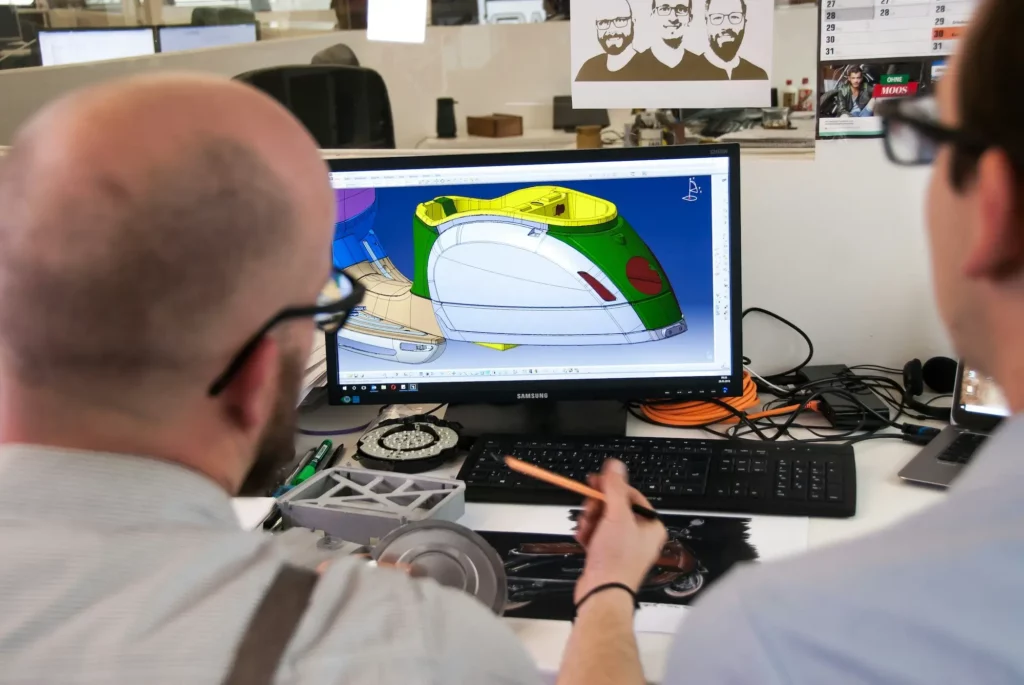

Design review tools made for reviewing CAD and 3D files can help a lot with collaboration. These tools let teams mark changes, leave comments, and track updates directly in the document during engineering design reviews without the need for downloading extra software.

It can also help non-technical stakeholders contribute to the project by making it easy for them to view and comment on the design without needing special training on the CAD software that engineers and manufacturers usually use.

Everyone can talk through changes and look at the same file together, and you can still protect data security by stripping internal notes before you send drawings outside the company.

Collaborate with Your Team in Real-Time with CADchat

CADchat makes CAD collaboration simple for everyone on the team. Whether you’re a designer, engineer, manufacturer, or non-technical teammate, CADchat helps you stay aligned without all the back-and-forth.

You can open 3D models live, talk through changes, leave comments, and track every update in one place, so the team can explain design intent right on the model and identify areas that need further approval before release.

There’s no need for screen sharing, extra tools, or long email threads. CADchat gives you critical features, such as asynchronous and real-time ways to share feedback, and it supports version control.

Every file, comment, and decision is saved in a shared workspace, so nothing gets missed.

If your team struggles with slow reviews, version mix-ups, or unclear feedback, CADchat can help. It brings everyone together and makes CAD collaboration easy.

Start using CADchat to simplify your workflow and work better as a team. Contact us today!

FAQs About CAD Best Practices

How do you standardize CAD practices across a team?

Set one shared template set, naming rule, layer rule, and review checklist, store them in one place, and train everyone to start every job from that setup.

What CAD standards should teams follow?

Follow the standard your field and buyers expect, like ISO 128 for drawing layout and ISO 129 for dimension rules in manufacturing, then add clear house rules for layers, text, and title blocks.

What causes most CAD project delays?

Teams lose time on unclear feedback, wrong file versions, messy file storage, and missing small details that force rework, plus slow handoffs to manufacturing.

How often should CAD design reviews happen?

Review at each big stage change and again before any release, and add quick checks after major edits so you catch issues early and avoid last-minute scrambling when generating reports.