Working with CAD files across different tools can be frustrating. Engineers might use one program, while manufacturers use another.

Files don’t always open right, formats don’t match, and feedback gets lost. These problems slow down progress and lead to mistakes that could have been avoided.

That’s where CAD interoperability comes in. In this article, we’ll explain what CAD interoperability means, why it matters, and how it helps your workflow.

What is CAD Interoperability?

CAD interoperability means different CAD systems and design feedback tools can read, write, or use the same data.

This helps users share data, such as CAD models, imported CAD data, and CAD formats, without needing to redraw or switch software.

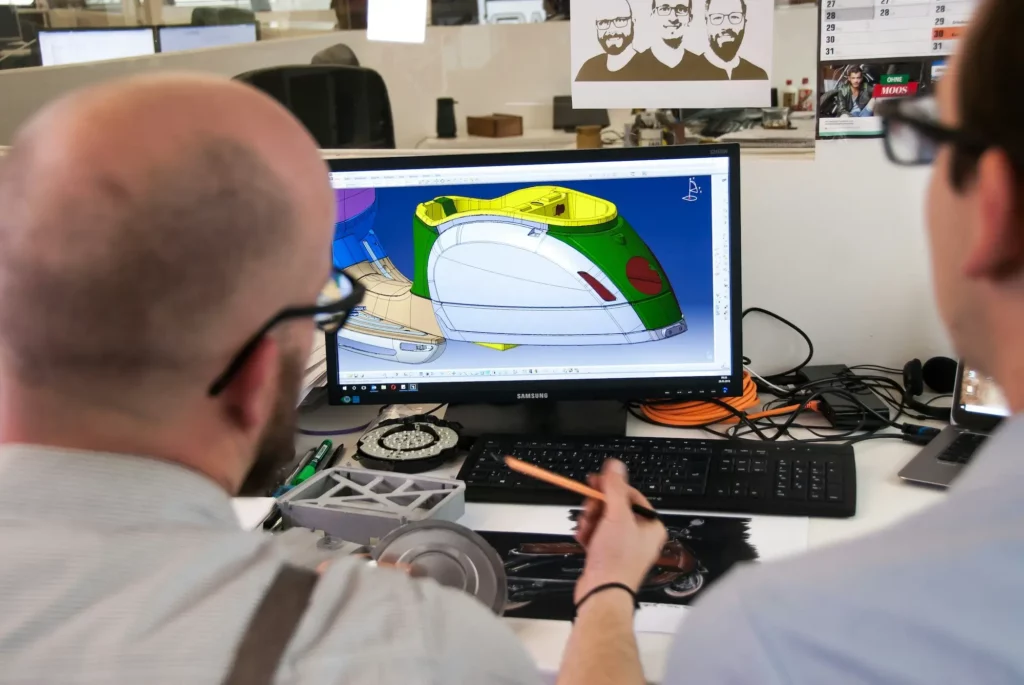

This is useful because engineers, designers, and manufacturers often use different tools during product development. For example, a designer may create a 3D model in one program, while a supplier reviews it using another. Without strong interoperability, the data exchange can cause problems.

Parts of the design may be lost, teams may need to repeat work, and unnecessary details can get added or removed during file transfers, making the design harder to follow.

These problems are often identified after delays, errors, or miscommunication have already caused setbacks.

Without a clear way to share files, it becomes harder for teams to stay aligned and focus on the design work.

CAD collaborative software can help fix this by making data sharing smooth and consistent. Teams can open and review the same design using different CAD tools.

Review designs from any major CAD system in one place. Try CADchat today!

Benefits of CAD Interoperability in Your Workflow

When implemented properly, CAD interoperability brings real improvements to your product development process. Here are some key benefits:

Faster Data Exchange

Interoperability allows teams to send and open files between different CAD tools without extra steps. This makes data exchange quicker and smoother.

Instead of waiting for file conversions or tool changes, teams can start working right away. It speeds up both design and production, helping projects move forward with fewer delays.

Better Team Collaboration

When everyone can open and review the same CAD model, even with different tools, CAD collaboration among teams improves.

CAD interoperability enables faster, real-time feedback and better teamwork. Teams can give feedback clearly, spot problems early, and share solutions quickly.

With a better understanding across the group, everyone from engineers to stakeholders can stay on the same page and work toward the same goals.

Reduced Rework

Problems like broken imports or missing parts often lead to rework. Interoperability helps prevent these issues by supporting clean and consistent file sharing.

Teams can stay focused on improving the design instead of correcting avoidable errors.

Easier Tool Integration

A workflow that supports multiple CAD systems can also connect easily with other tools, such as simulation, testing, or manufacturing software.

This creates a smoother, more flexible process across different departments and partners.

Optimized Use Of Resources

Time spent fixing file problems or searching for the latest version adds up. Interoperability helps teams avoid these setbacks, allowing more time for meaningful work.

During engineering design reviews, teams can focus on feedback and improvements instead of chasing files or correcting errors.

Tools, people, and processes are used more effectively, leading to stronger results and faster progress.

Reduce delays caused by incompatible file formats by 50%. Review designs in CADchat.

How CADchat Improves CAD Interoperability

CADchat is a cloud-based meeting and collaboration tool made for product teams that work with CAD files.

It helps engineers, designers, manufacturers, and even non-technical team members stay aligned during the product development process.

One of the strongest parts of CADchat is its support for CAD interoperability. Let’s look at a few reasons why

Works With All Major CAD Formats

CADchat is CAD file format agnostic, which means it supports files from all major CAD tools. You don’t need to ask someone to switch their software or waste time converting files. It works across different CAD systems without the need for file conversions or software changes.

Whether your model comes from SolidWorks, CATIA, Creo, or another system, you can upload and work with it right inside CADchat. This gives your team more flexibility and saves time during design reviews and decision-making.

No File Conversion Needed for Accessing CAD Data

Instead of forcing teams to convert files to a common format, CADchat lets you open native CAD files directly.

Reducing the risk of data loss helps keep your design details intact. You also avoid wasting time on extra steps, which speeds up collaboration across different tools and teams.

Keeps Everyone On The Same Version of CAD Models

File version problems are common when different people work with different tools. CADchat keeps a single, updated version of the CAD file in one place.

Everyone sees the same design and can track changes clearly. This helps reduce errors, avoid repeated work, and keep everyone on the same page.

Makes Collaboration Easier For Mixed Teams

CADchat is not just for technical users. Anyone on the team, even those without CAD software or training, can open models, leave feedback, and follow the discussion.

This makes it easier for product teams to stay aligned and make smart decisions faster, without slowing down for software issues.

Work across design tools without slowing down. CADchat makes it easy!

FAQs About CAD Interoperability

What is CAD interoperability?

CAD interoperability means different CAD tools can use the same data. It makes it easier for teams, tools, and agencies to communicate and support each other across engineering, simulation, and analysis tasks.

What do you mean by interoperability?

Interoperability means that different platforms, such as Solid Edge, SolidWorks, Catia, or NX, can exchange and understand data and metadata of varying standards without issues.

It helps reduce unnecessary details during data exchange and supports better collaboration across engineering teams and software systems.

What are the three types of CAD?

The three types of CAD are 2D drafting, 3D modeling, and 3D parametric modeling. These help create and manage CAD models for engineering, supply chain support, file translation, simulation, and model simplification.

Different CAD systems like SolidWorks, NX, SolidEdge, and Catia serve different needs depending on the level of detail, documentation, and visualization required.

What is the difference between CAD interoperability and CAD in public safety?

CAD interoperability is about allowing different CAD systems and software platforms to exchange design data and files for uses like product development, simulation, or supply chain communication.

On the other hand, CAD in emergency response refers to Computer-Aided Dispatch, used by public safety agencies to dispatch responders to incidents.