Engineering design reviews can feel messy. People show up with different versions of the design. Some team members don’t have the right tools to open the file.

Others feel lost in technical talk. Meetings go long, and follow-ups get missed. By the end, no one is sure what was decided or who’s doing what.

In this article, we’ll walk through simple steps to help you run effective engineering design reviews that actually work.

Why Are Engineering Design Reviews Important?

An engineering design review is a planned meeting where teams come together to look at a design, check if it meets project goals, and give feedback. It is a mix of technical review, team discussion, and project review.

These reviews usually include the mechanical engineering team, designers, and product teams. Sometimes, these meetings are also done to collaborate with suppliers and update customers.

The goal is to catch common CAD design issues early, share input, and make better design choices before moving forward.

Here are some of the main reasons these reviews matter:

Catch Problems Early

A design might seem fine at first, but a technical review can help find issues that are easy to miss. Team members can present concerns, point out weak spots, and help determine the right changes. This helps avoid delays and rework later.

Get Input From Everyone Involved

These reviews are not just for engineers. They let everyone involved in the project give design feedback. Product teams, customers, and even people from marketing or support can participate. Each person brings a different view that can improve the final result.

Create Clear Documentation

Good reviews lead to good records. You can add meeting notes, screenshots, and meeting minutes to keep track of what was said and done. This helps everyone remember the key points and know what steps to take next.

Keep Context And Background In One Place

When reviews happen online, it’s easier to document everything. You can link to a shared article, a product page, or other relevant files. This gives people the full background they need to understand the review and make smart decisions.

Make It Easy To Respond And Follow Up

Online tools make it simple for people to respond on their own time. You can schedule live meetings or let team members comment when it works for them. This makes it easier to keep everyone involved, even across time zones.

Help The Team Work Better Together

Engineering design reviews create a collaborative space for thoughtful feedback and expectations.

When teams take time to review designs together, they catch mistakes early, spot better solutions, and make smarter decisions as a group, all of which leads to better project success.

Having regular engineering standups can also help keep everyone in sync with daily progress and blockers.

These meetings help align engineers, designers, and other participants around the same goals. Everyone gets a chance to ask questions, raise concerns, and agree on what happens next.

How to Facilitate a Successful Engineering Design Review

Whether your team is full of engineers or includes non-technical stakeholders, too, a few key steps can make the engineering design review process easier for everyone.

Here’s how to do it right.

Set A Clear Goal For The Review

Every design review should start with a clear goal. What are you trying to achieve? Are you collecting feedback on a new concept? Approving final specs? Checking if a design is ready for testing, production, or ready to implement?

The goal might be to review feasibility, suggest areas for improvement, or assess the quality of the design before moving forward.

When the goal is clear, people show up prepared. They know what to look for and what kind of feedback to give. This saves time and keeps the review focused. Without a clear purpose, the conversation can drift, and important points may be missed.

Make sure to write the goal down and share it with the team before the review. That way, everyone’s on the same page from the start.

Invite The Right Mix Of People

A successful design review includes both technical and non-technical voices. Engineers look at how the product works. Product managers think about how it fits user needs. Clients may care about timelines or cost. Each person brings a different view, and that’s a good thing.

If your review only includes technical people, you might miss feedback about usability, branding, or business goals. If it only includes non-technical people, important design issues might not get caught.

To make the review meaningful, invite people who can speak to different parts of the project. Encourage open, respectful discussion and give everyone a chance to be heard.

Stick To A Simple, Clear Agenda

A design review can cover a lot, but it shouldn’t try to cover everything at once. That’s where a simple agenda helps. Start with a quick overview of the design. Then go through the model section by section. Make space for questions and comments along the way.

By following a clear order, you keep the discussion moving. It also helps prevent one topic from taking over the entire meeting.

At the end, take a moment to summarize what was discussed and what needs to happen next. This step helps lock in the key takeaways and avoids confusion later.

Support Both Real-Time And Asynchronous Reviews

Not every team works in the same place or time zone. That’s why design reviews should work in both real-time and asynchronous ways.

Live meetings are great for fast feedback and group discussion. Still, sometimes, teammates need more time to look over the design and add thoughtful comments. Maybe they’re in a different time zone. Maybe they’re busy with other tasks.

Allowing people to give input on their own time keeps the project moving. It also gives space for quieter team members to contribute. The result is a better, more complete review.

Document Feedback And Next Steps

After the review ends, it’s easy to lose track of what was said. That’s why documenting feedback is so important. Write down key decisions, open questions, and follow-up tasks. Share them with the team right after the review.

It’s also helpful to include any suggestions, design guidelines, or input based on team expertise. These details make it easier to take the right next steps.

Make sure everyone knows what they’re responsible for and when things are due. This avoids miscommunication and keeps the project moving.

The best design reviews lead to action. Clear notes and task lists turn feedback into progress, which makes follow-through an essential part of the process.

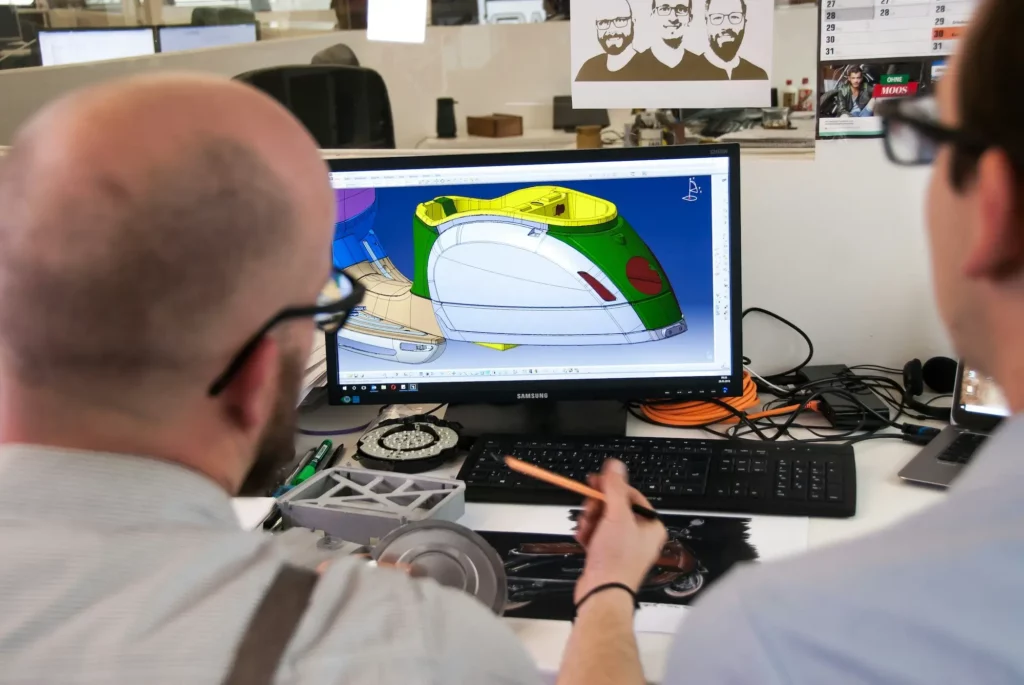

Use Tools That Make CAD Collaboration Simpler

Reviewing CAD files can be difficult, especially when teams rely on screen sharing, emailing screenshots, or large file transfers.

These methods often cause confusion, slow down feedback, and make it harder for non-technical teammates to stay involved. That’s why using the right CAD collaboration tools can help.

Tools like CADchat let teams view and discuss CAD files in real time or leave feedback whenever it works for them.

Everyone can look at the same model, add comments in context, and stay on the same page. With built-in CAD interoperability, there’s no need to switch between different apps or worry about outdated files.

When all feedback, files, and decisions are stored in one place, it becomes much easier to keep track of what was reviewed, what changed, and what needs to happen next.

Following this approach also supports best practices for product design by keeping everything organized, easy to reference, and helps keep the project moving in the right direction.

Make Your Next Design Review Simple With CADchat

If your team works with 3D models and CAD files, CADchat can help you run smoother, faster, and more focused design reviews.

You can open 3D models in your browser, meet with engineers and stakeholders, and leave comments right on the design. Whether your team works in real time or across time zones, everyone can stay involved and up to date.

With live model reviews, asynchronous feedback, and shared digital workspaces, CADchat makes it easy to keep all files, comments, and decisions in one place. You don’t have to worry about version control, scattered feedback, or missed updates.

No more screen sharing. No more long email threads. Just clear communication, better teamwork, and faster decisions.

Technical vs Non-Technical Engineering Design Review

Before making a product, teams need to check the design. This helps catch mistakes early and keeps everyone on the same page. But not everyone looks at the design the same way.

That’s normal. And it’s actually a good thing, as long as the review process makes room for both views. That’s why we have a technical and non-technical design review. Let’s look at how they differ from each other.

- A technical design review is for engineers and technical team members. They focus on materials, tolerances, how parts fit, and how easy it is to build the product. These reviews usually happen inside CAD software using detailed drawings.

- A non-technical design review is for people who don’t use design tools every day. This could include product managers, marketing teams, clients, or even company leaders. They care more about how the product looks, if it meets business goals, how easy it is to use, and if it fits the budget and timeline.

The main difference is what each group focuses on and how they review the design. Technical teams look at the details. Non-technical teams focus on the bigger picture. Still, both sides need to give input and work together.

Main Types of Engineering Design Review

Design reviews help teams catch problems early, improve the design, and stay aligned. There are several types of reviews, and each one happens at a different stage of the project.

Let’s walk through the main ones, one by one.

Preliminary Design Review (PDR)

This is one of the first big review steps in a project. The team looks at the early design ideas and checks if they make sense.

Engineers talk about what’s working and what needs more thought. The group looks at possible strengths and weaknesses in the design concepts.

After this review, the team usually updates the plan based on the feedback. It helps shape the direction of the project before going deeper into the details.

Critical Design Review (CDR)

This review is more detailed than PDR. It usually happens right before the project moves into the next phase.

At this point, the design is almost final, and the team needs to make sure everything is solid. Engineers check every part of the design to find issues before building or testing starts.

If something is missing or unclear, this is the time to fix it. A strong CDR helps avoid problems later in the process.

Test Readiness Review (TRR)

Once the team is ready to test the product, they hold a TRR. This review checks that all test plans and tools are in place. It also makes sure the product meets the requirements needed for testing.

The team looks at the test setup, equipment, and goals to confirm that everything is ready. TRR helps avoid wasted time and failed tests due to poor planning or missing parts.

Final Design Review (FDR)

After testing is done, the team comes back for the FDR. In this review, they talk about the test results and any problems found during testing.

If there were issues, the team will discuss how they were fixed. FDR is the last chance to review the design before moving into production. It helps confirm that the product works as expected.

Production Readiness Review (PRR)

This review happens after the first manufacturing runs. The team looks at the results from early builds, often called first article inspections (FAI). They check if the product can be built properly and whether the process works well.

PRR also helps update the estimated costs of making the product. If anything needs to change before full production, this is the time to talk about it.

FAQs About Engineering Design Reviews

What is an engineering design review?

An engineering design review is a formal design review process where the design team meets with subject matter experts and other stakeholders to evaluate the design at various stages of the development process.

It helps identify potential issues early, provides feedback, and improves outcomes before moving to the next phase.

This review plays a crucial role in keeping everyone on the same page, checking the design against project objectives, and making sure the team is heading in the right direction.

What is the difference between a CDR and a PDR?

A preliminary design review (PDR) happens early in the design process to check if the concept is feasible and matches the project scope.

A critical design review (CDR) comes later, once the detailed design is mostly complete, to see if the design is ready for manufacturing or building a prototype.

Both are common types of engineering design reviews, but they focus on different points in the development.

What is the difference between DDR and PDR?

A PDR checks the high-level design and helps make sure the system concept and structure are on track.

A detailed design review (DDR) looks closely at all the specifications, materials, drawings, and details of the system before finalizing.

The PDR happens earlier, while the DDR focuses on the finer aspects and is more about confirming that everything is ready for the next phase.

What is the difference between PDR and FDR?

The PDR checks the basic design idea to see if it’s worth building, while the final design review (FDR) happens just before launch or manufacturing.

FDR is the last formal design review where the design team, along with engineers and other people involved, confirm that the system meets all requirements.

It’s the point where the design is locked down, and no major changes are expected unless needed.