Working with external suppliers can be tough. Communication gaps, delays, and last-minute changes often slow things down.

When teams are not aligned, small issues can grow into bigger problems that affect cost, timing, and product quality.

In this article, we’ll talk about 11 practical strategies to improve supply chain collaboration. With the right approach and supplier collaboration tools, your team can stay in sync with its external partners and create a more efficient supply chain network.

What Is Supply Chain Collaboration?

Supply chain collaboration means working together with other companies to carry out supply chain processes. This often includes external partners like suppliers, manufacturers, and logistics teams.

In global supply chains, these groups may be spread across different regions, which makes communication and timing more complex.

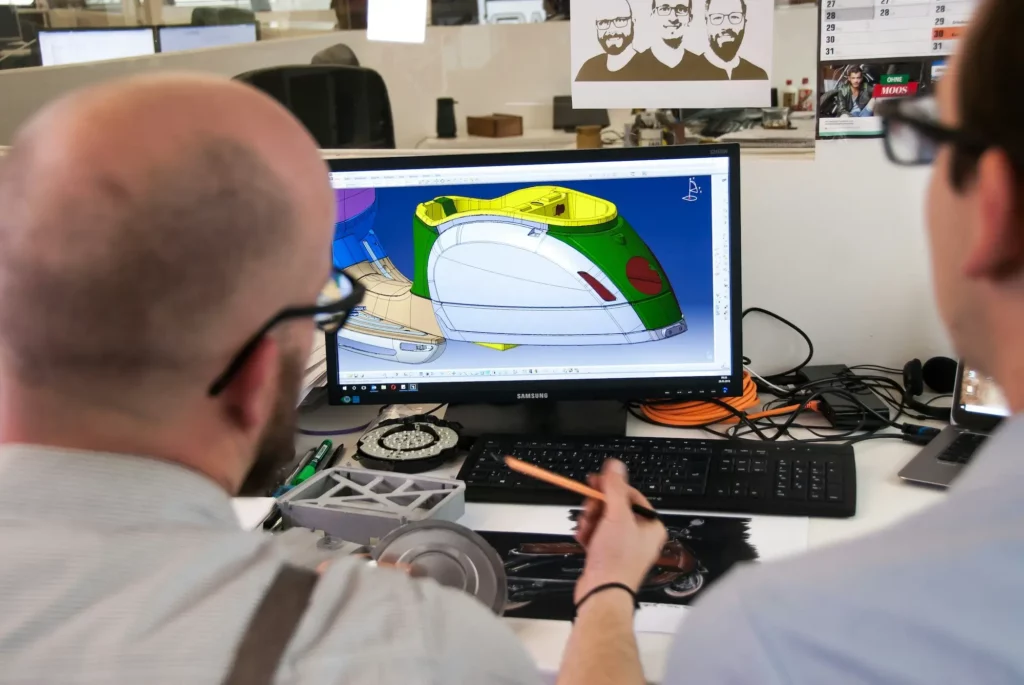

Product design depends on this kind of teamwork. As a product is being developed, design teams need input from suppliers about available materials, costs, and lead times. These supply chain activities affect what can be made, how fast, and at what price.

Each group handles different supply chain functions, but they all need to stay aligned. There are many stakeholders involved, and without clear updates, communication gaps can slow down progress or cause mistakes.

Share 3D designs and resolve supplier feedback faster with CADchat.

11 Strategies to Improve Supply Chain Collaboration

Strong supply chain collaboration doesn’t happen by chance. Here are 11 strategies you can try to improve collaboration with your suppliers.

1. Share Information Early and Often

One of the best ways to improve supply chain collaboration is to keep everyone informed from the start. Sharing updates as early as possible helps teams avoid confusion and stay aligned.

When suppliers and internal teams have access to the same details, decisions can be made faster and with fewer mistakes.

Seamless data sharing plays a big role here. It allows everyone to track changes, review timelines, and understand what’s needed at each step.

Collaborative forecasting also becomes easier when data is shared regularly. Suppliers can prepare for demand shifts, and design teams can adjust plans based on real-time input.

Early and frequent communication builds trust and keeps the supply chain moving without surprises.

Cut down on back-and-forth emails and get supplier feedback faster with CADchat.

2. Open Up Across All Tiers

Strong supply chain partnerships depend on open communication with every group involved. This means going beyond direct suppliers and including second and third-tier partners as well.

When everyone receives the same updates, all teams stay on the same page and can plan with better accuracy.

In the design review process, even a small change can affect suppliers further down the line. If those partners are left out of the loop, delays, shortages, or mistakes can happen. That is why clear communication across all levels is so important.

By opening up across all tiers, companies build stronger supply chain partnerships. Every team understands its role and timing, which helps avoid last-minute issues.

3. Use Real-Time Communication Tools

Getting real-time feedback and updates helps teams avoid delays and confusion. As such, tools that support live messaging, shared dashboards, advanced analytics, and file updates are important in making sure everyone is in sync.

Many companies now use product collaboration software to connect design teams with supply partners.

These tools allow both sides to review specs, track changes, and give feedback quickly. Real-time access helps speed up decisions and reduces long back-and-forth email threads.

When paired with enterprise resource planning systems, these tools become even more useful. They pull in data from different departments so teams can see the full picture.

4. Align on Clear Goals

Clear goals keep everyone focused and working toward the same outcome. When supply chain teams and external partners agree on what matters most, it becomes easier to stay aligned throughout the process.

This is especially important during product development, where changes can affect timelines, costs, and supply plans.

Start by setting shared goals that support your supply chain strategies. These might include faster lead times, better quality, or lower costs. Everyone involved should understand what success looks like and what their role is in reaching it.

It also helps to track progress using key performance indicators (KPIs). These give a simple way to measure how well each team is doing and where things need to improve. With clear goals and shared metrics, CAD collaboration becomes more focused and productive.

Collaborate across time zones with suppliers using CADchat’s tools.

5. Build Trust Through Transparency

Good communication builds trust. That starts with being clear about what you need, when you need it, and what might cause delays.

Let your suppliers know about any changes in design, timelines, or order volumes. At the same time, ask them to share risks or possible CAD issues as soon as they see them.

This back-and-forth helps both sides prepare and adjust without losing time. Being open helps maintain strong supplier relationships.

When both sides are honest and proactive, trust grows over time. That trust leads to smoother collaboration, fewer surprises, and better results across the entire supply chain.

6. Focus on Performance Metrics

Tracking the right numbers helps teams find what’s working and what needs fixing. Key metrics like delivery time, defect rates, and inventory levels show how well your supply chain is running. These numbers give a clear view of progress and help guide better decisions.

Sharing performance data with your suppliers is just as important. When they can see how they’re doing, it becomes easier for them to spot issues and make improvements. This creates a more open and productive working relationship.

Watching these metrics closely often leads to improved efficiency. You can respond to delays faster, fix quality problems early, and adjust inventory before it gets too high or too low.

When everyone is working from the same numbers, it’s easier to stay aligned and keep the supply chain running smoothly.

7. Meet Regularly With Supply Partners

Design review meetings give everyone a chance to talk about progress, go over design changes, and deal with problems before they get worse. When product teams, suppliers, and logistics providers meet often, they stay in sync.

Short weekly calls or inviting them to your team’s engineering standups work well for fast updates. These don’t need to be long. A quick review of what’s done, what’s coming next, and any risks is enough to stay aligned.

Meeting regularly also builds stronger working relationships. People are more likely to speak up, share concerns, and offer ideas when they talk often.

This habit creates trust and helps everyone move together. In supply chain work, clear and steady communication is one of the best ways to avoid delays and improve teamwork.

8. Be Proactive, Not Reactive

Waiting for problems to happen can lead to delays and missed deadlines. A better approach is to ask questions early.

Talk to your suppliers about disruptions, upcoming changes, or new design needs. Find out if they have backup plans, extra capacity, or quality control steps already in place.

This kind of early planning supports robust risk management strategies. It helps teams stay ahead of issues instead of scrambling to fix them later.

Regular checks and open conversations make it easier to spot weak points and adjust before they cause trouble.

Being proactive also plays a big role in enhancing supply chain resilience. When everyone is prepared, the supply chain can handle changes without slowing down. This leads to smoother operations and more dependable results throughout the entire process.

9. Co-Design With Suppliers

Involving suppliers early in the product development phase can prevent problems down the line. By asking for their input on material choices and how parts will be made, teams can avoid costly redesigns and delays.

Suppliers often see things that design teams might miss, especially when it comes to manufacturing limits or delivery times.

Using CAD collaboration software makes it easier to share models, leave comments, and make changes in real time.

This helps both sides stay aligned and reduce back-and-forth later. When suppliers can give early feedback, designs are more likely to meet both quality and cost goals.

Working together also helps optimize inventory levels. Suppliers can suggest materials that are easier to source or quicker to deliver, which supports better planning and fewer stock issues. Co-design builds stronger teamwork and smoother production from the start.

10. Invest in Digital Supply Chain Platforms

Digital supply chain platforms help teams stay connected by bringing sourcing, procurement, and design into one system.

When everyone works from the same data, it becomes easier to track progress, share updates, and avoid miscommunication. This reduces silos between teams and cuts down on rework caused by outdated information.

Many of these platforms now include AI and machine learning features. These tools can predict delays, suggest better suppliers, and flag risks before they cause problems. They also help teams make faster, smarter decisions based on real-time data.

You can also add a design feedback tool to gather input directly within the system. This helps engineers and suppliers stay aligned without switching between apps.

By choosing to leverage advanced technologies, companies can improve teamwork, reduce errors, and keep supply chain activities running smoothly.

11. Stay Flexible and Ready for Change

Supply chains don’t stay the same for long. Markets shift, materials run short, and product designs change. To keep up, teams need to be flexible.

A strong collaboration setup makes it easier to adjust when plans need to change. This helps you and your suppliers respond quickly without slowing down production.

One way to support this is through seamless integration between your systems and your suppliers’ tools.

When data flows easily, updates happen faster and with less confusion. This saves time and keeps everyone working from the same information.

Flexibility also means being open to new ideas, switching materials when needed, or changing timelines to meet new demands. With good communication and the right tools in place, supply chain teams can keep moving forward even when things change.

Simplify design-to-supplier handoffs with a shared CAD workspace. Try CADchat.

Benefits of Supply Chain Collaboration for Product Design

Working together early in the design stage can make a big difference. Below are some of the main benefits you can expect from a successful supply chain collaboration:

Improved Inventory Management

Design choices affect what materials are needed, how much, and when. By involving suppliers early, teams can plan orders with better timing and volume.

This leads to optimized inventory management, with fewer shortages and less overstock. Better visibility across supply points also reduces waste and storage costs.

Lower Transportation Costs

Early coordination makes it easier to schedule regular shipments and avoid last-minute rush orders.

When delivery times are predictable, businesses can choose more efficient shipping options. This lowers transportation costs and reduces the risk of delays or added fees.

Better Cost Reduction

Working with suppliers during design helps catch expensive ideas before they go too far. If a material is too costly or hard to source, teams can make changes early.

These decisions lead to simpler builds, easier sourcing, and lower overall costs during production.

Increased Operational Efficiency

Clear planning reduces confusion between departments and outside partners. With fewer surprises, production moves faster, and teams waste less time fixing problems.

Everyone works from the same plan, which helps improve how tasks flow from design to delivery.

Stronger Competitive Edge

Speed and accuracy matter in product launches. Teams that stay aligned with external partners can move faster from idea to market.

That gives them a clear competitive edge, especially in industries where timing and reliability are hard to balance.

Enhances Customer Satisfaction

Products that arrive on time and meet expectations reflect well on the entire company. Strong supply chain communication supports better design, better production, and smoother delivery.

Customers notice when things go right, and that often begins with early collaboration behind the scenes.

Bring Your Suppliers Into the Loop with CADchat

Suppliers play a big role in getting your product built, but working with them often leads to long email threads, missed details, and delays. CADchat gives your team a better way to collaborate with suppliers in real time or on their own schedule.

With CADchat, you can invite suppliers to view and comment directly on CAD files. They don’t need special software or CAD expertise.

They can just open the file, review the model, and leave feedback right where it’s needed. That means fewer misunderstandings and faster problem-solving.

If a part looks hard to manufacture, your supplier can flag it. If something needs to change, they can explain why and suggest a fix.

Everything is saved in one place, so your team can track feedback, follow up quickly, and stay aligned with your partners.

No need to schedule extra meetings or convert files. Just drop the CAD model into your workspace, tag your supplier, and keep the work moving forward.

Try CADchat today and make supplier collaboration simple, fast, and clear.

FAQs About How to Improve Supply Chain Collaboration

How to improve supply chain coordination?

To improve supply chain coordination, businesses should focus on real-time data sharing, transparent communication, and strong relationships with supply chain partners.

Using a supply chain collaboration platform like CADchat helps align production schedules, demand forecasts, and inventory levels across the supply chain.

This improves supply chain responsiveness, cuts operational costs, and boosts customer satisfaction.

What are the 7 C’s of SCM?

The 7 C’s of supply chain management usually refer to customer focus, collaboration, coordination, communication, control, commitment, and continuous improvement.

These support effective supply chain collaboration by improving supply chain operations, supplier relationships, and overall supply chain efficiency.

When these areas work together, it becomes easier to manage complex supply chains and improve supply chain performance.

How can collaboration among supply chain partners optimize performance?

Collaboration among supply chain partners helps optimize performance by aligning business processes, reducing inventory holding costs, and improving supply chain resilience.

With real-time demand forecasts and seamless coordination, partners can better manage supply chain disruptions and respond faster to market trends.

This leads to cost savings, better inventory management, and a more responsive and effective supply chain.