If your product team wants to explore mechanical engineering design hands-on, building sample projects is a great way to start.

These sample mechanical projects can help you and your team understand how ideas turn into real systems and can give your team a chance to test concepts in a practical way.

In this article, we’ll look at five mechanical design examples your team can experiment with.

What Is Mechanical Design?

Mechanical design, also called mechanical engineering design, is the process of making machines, tools, and systems that help solve real-life problems.

It turns ideas into working products that serve a clear purpose. You begin by defining the problem and setting specific goals for your design projects. Then you research, plan, and explore possible solutions before moving into sketches and detailed models.

After planning, mechanical designers build a prototype to test how the design performs. This helps you find issues early and make improvements before production.

Each change brings you closer to your primary goal of making a reliable, safe, and efficient product that meets all requirements.

Mechanical design combines creativity and logic. It plays a key role in the manufacturing process, turning concepts into functional mechanical systems that last and work well.

Book a demo today and see how CADchat simplifies feedback and collaboration in mechanical design.

The Role of Computer-Aided Design (CAD) Software in Mechanical Engineering

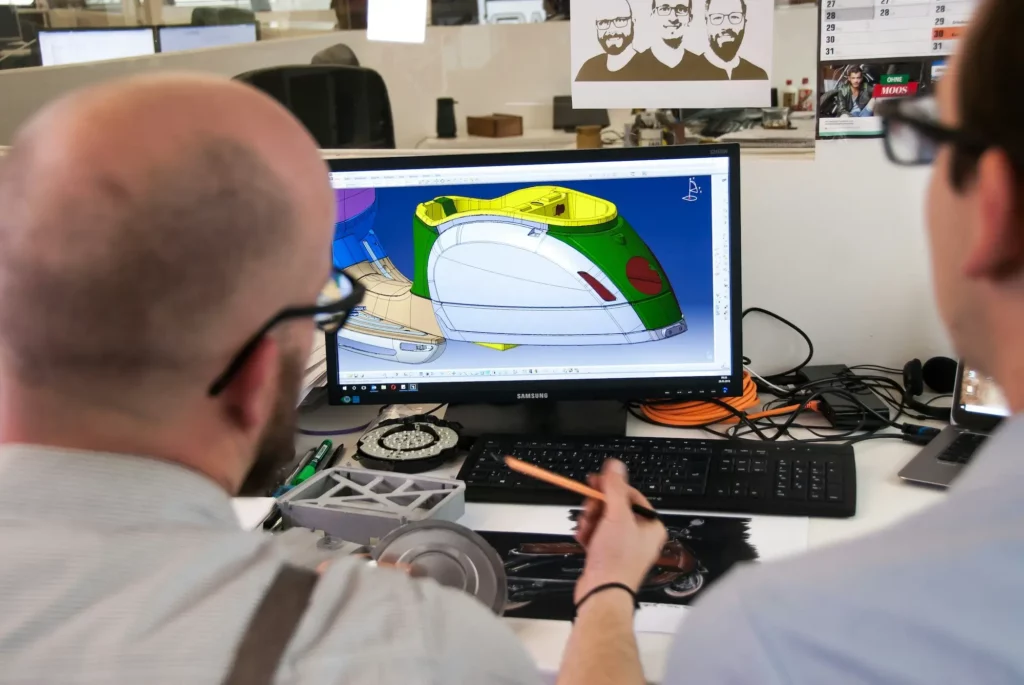

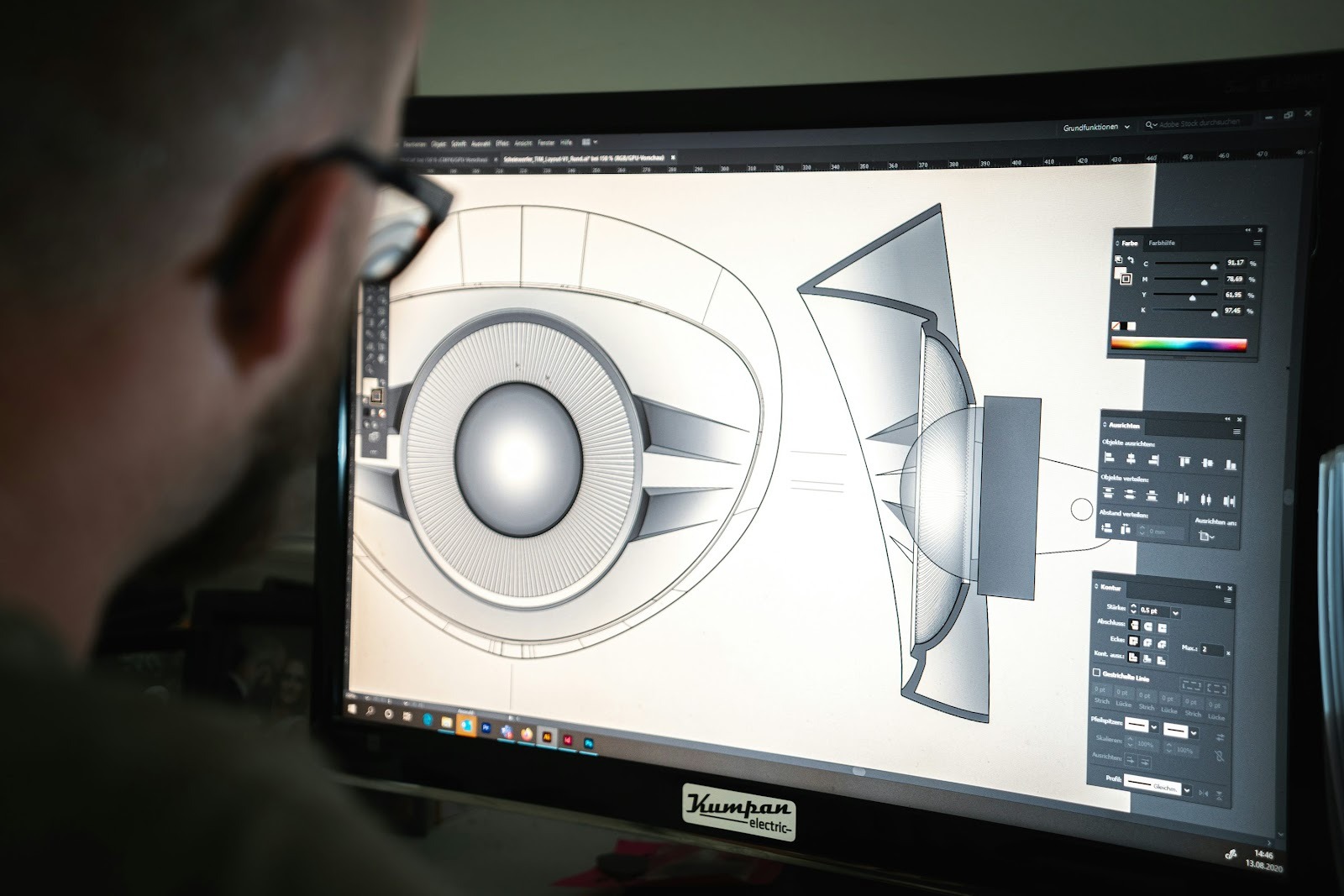

CAD software gives product teams the tools to turn ideas and concepts into detailed 2D drawings and 3D models that represent real parts, structures, and systems.

CAD helps your engineering team move from imagination to creation while reducing mistakes and improving accuracy.

It also makes it easier to determine how different parts will connect during assembly and perform under real conditions.

Here are the key roles and benefits of CAD software in mechanical engineering:

- Precision and accuracy: CAD allows you to design parts with exact dimensions, so every piece fits perfectly during assembly.

- Efficiency and focus: You can spend more time improving technical aspects of the design instead of doing repetitive manual work.

- Visualization: CAD lets you view your model from every angle, helping your engineering team communicate complex concepts clearly.

- Simulation and testing: Using finite element analysis, you can test how your design performs under pressure, heat, or motion before building a prototype.

- Collaboration: Cloud-based tools keep everyone connected, allowing teams to share updates and work together on innovative solutions.

The Mechanical Design Process

The mechanical design process is how you move from a simple idea to a working product. It gives your engineering team a clear path for solving problems and creating designs that are practical, efficient, and ready for production.

Each step focuses on refining individual components, testing them under real or simulated environmental conditions, and preparing them for the production process.

Define the Problem

The first step is understanding what you need to design and why. You define the challenge, objectives, and limits. This may include talking with sponsors or clients to align expectations.

For example, if you are designing compact devices, you might focus on space limits, weight, and battery life. This stage helps you clearly identify what success looks like before you begin.

Generate Ideas

Once you understand the problem, you start brainstorming possible solutions. You can sketch early components, draw quick layouts, or model rough shapes.

The goal is to explore creative ways to solve the problem without worrying about perfection yet. At this stage, more ideas often lead to stronger final designs.

Select and Develop Concepts

Here, you evaluate your best ideas based on feasibility and practicality. You think about material selection, production costs, and performance under environmental conditions.

You refine your top concepts into detailed designs, add precise dimensions, and start testing them through simulation or calculation.

This is a transformative phase, where rough concepts start turning into real mechanical designs.

Detailed Design

Now it’s time to finalize everything. You produce accurate drawings and specifications, prepare the bill of materials, and include all the individual components needed for manufacturing.

You also run deeper engineering checks to confirm that the design will perform well under expected environmental conditions. At this point, your design should be ready for prototyping.

Prototyping and Testing

You create prototypes using CAD tools or physical models. Testing helps you confirm performance and spot problems early.

For example, you might test how compact devices handle heat or how software components interact in the design. Adjustments made during this step help make your product safer and more reliable.

Production Planning

In the final stage, you prepare for manufacturing. You plan workflows, choose machines and tools, and look at ways to lower production costs while maintaining quality.

This step also involves organizing the production process, from assembly to quality checks. When finished, your mechanical design is ready to move from prototype to full production.

Book your demo now and learn how CADchat helps engineers share and discuss models without confusion.

5 Mechanical Design Examples Your Team Can Try Making Today

If you want to practice your design skills or try something new with your team, small mechanical projects are a great way to start.

We gathered these design samples from Nevon Projects, a well-known source for engineering and mechanical design ideas.

Each example is simple enough to build in a lab or workshop, yet detailed enough to help your team understand how mechanical systems work together.

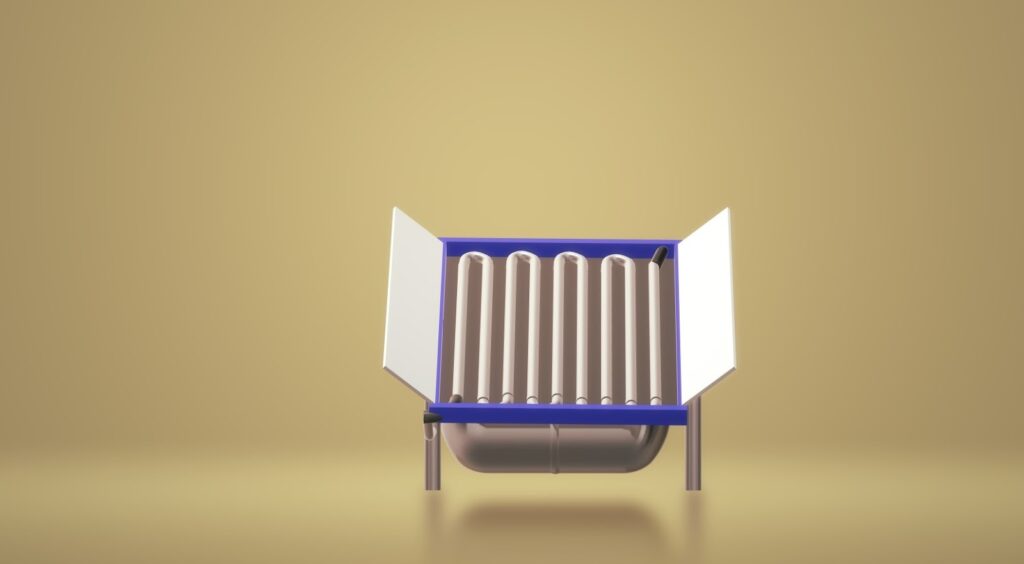

1. Mini 20-Liter Solar Water Heater

Source: nevonprojects.com

This solar water heater project is a compact solar-powered water heater designed to help you save electricity while still providing warm water efficiently.

Traditional electric water heaters consume around 2,000 watts, but this design needs only about 30–50 watts since it mainly depends on solar power. It’s an ideal small-scale project for your team to explore how solar heating systems work in real life.

To build it, you’ll use steel pipes arranged in a coil to let water pass through. Sunlight directly heats these pipes, and a black-painted metal back plate helps absorb extra heat.

Two reflective sheets are placed around the coil to bounce sunlight back onto the pipes, increasing efficiency.

A pump motor moves water through the pipes and back into the tank until it reaches the desired temperature.

This setup helps your team understand heat transfer, solar energy use, and mechanical design principles related to sustainable heating systems. It’s a hands-on way to see how small adjustments in design can create major energy savings.

Materials needed:

- Steel pipes

- Water tank

- Pipe connectors

- Pipe fittings

- Water pump (low-power motor, up to 50W)

- Reflector sheets

- Back sheet (metal, black-painted)

- Hinges

- Supporting rod pipes

- Mounts and joints

- Base frame

- Supporting frame

- Screws and fittings

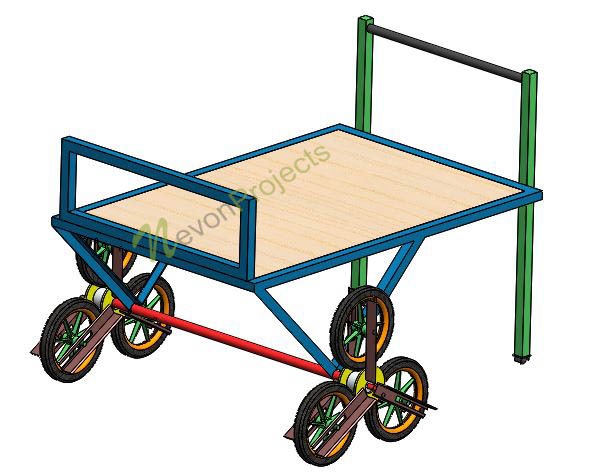

2. Staircase Climbing Trolley

Source: nevonprojects.com

The staircase climbing trolley is designed to make moving heavy goods over stairs easier and safer. Traditional trolleys can only move on flat ground, which makes carrying items upstairs or downstairs difficult and tiring.

This project helps you create a smart trolley that can handle flat surfaces, stairs, and even rough terrain with less effort.

The design uses a triple-wheel mechanism. Each set of three wheels is connected to a central rotating rod through connecting shafts and bearings.

As the trolley moves over the steps, the wheels rotate around the center rod, allowing the next wheel to grip the next step smoothly. This continuous rotation makes the trolley climb or descend stairs without losing balance.

To build it, you’ll need wheels, connecting rods, bearings, and a goods holder frame to carry items. The handle rods and supporting frame provide stability, while mounts, joints, and screws keep the structure secure.

This project teaches your team how to design mechanical linkages that solve real-world transportation problems.

Materials needed:

- Wheels

- Bearings

- Connecting rods

- Goods holder frame

- Handle rods

- Support rods

- Mounts and brackets

- Supporting frame

- Joints and screws

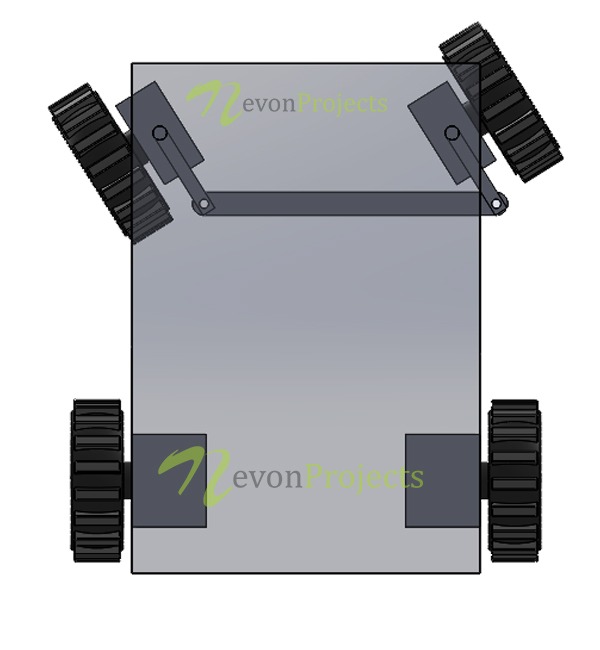

3. Robotic Vehicle Using Ackermann Steering Mechanism

Source: nevonprojects.com

This project is about building a small robotic vehicle that uses the Ackermann steering mechanism, the same system used in cars.

Unlike differential or skid steering, which causes wheel slippage and wastes energy, Ackermann steering allows all wheels to turn around the same center point. This makes the robot’s movement smoother, more accurate, and more energy-efficient.

In this project, your team will design and assemble a mini robotic vehicle that demonstrates this principle. The robot uses a set of wheels, rods, and links connected through shafts and couplings.

These parts create the steering geometry that lets both front wheels turn at slightly different angles during a turn, helping the robot move naturally without sliding.

To build it, start by designing the supporting robot frame to hold all parts firmly. Then attach the Ackermann linkage system to the front wheels and connect it to a steering servo motor or manual control, depending on your setup.

This project helps your team understand real-world steering systems and energy-efficient vehicle movement. It’s perfect for learning how mechanical motion translates into controlled steering.

Materials needed:

- Wheels

- Rod

- Link

- Shaft

- Couplings

- Supporting robot frame

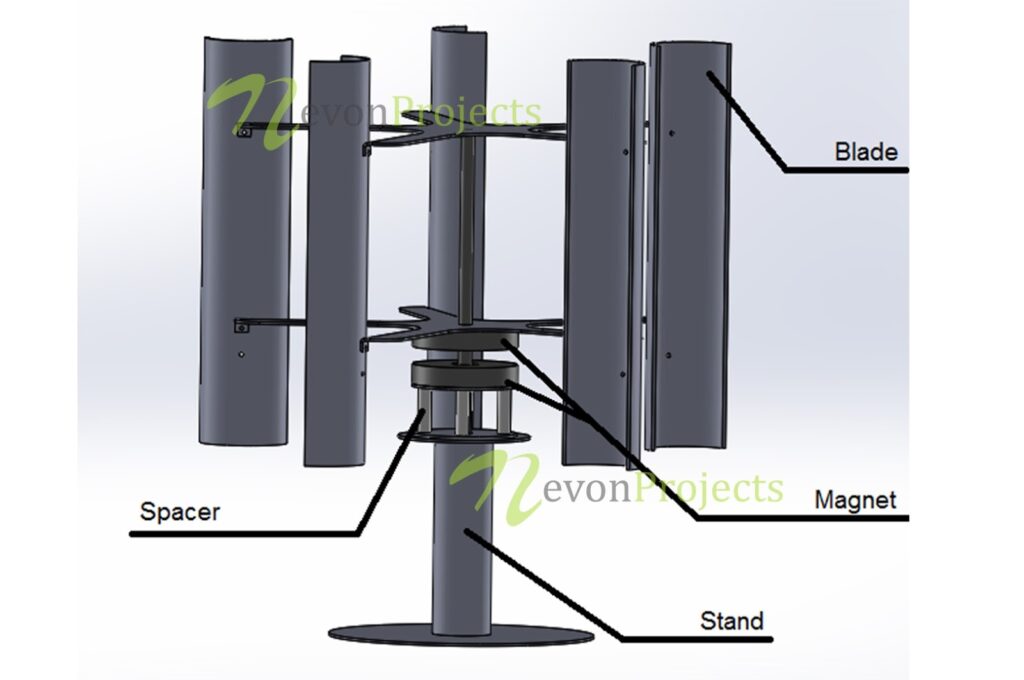

4. Levitating Frictionless Vertical Windmill

Source: nevonprojects.com

The Maglev wind turbine is an advanced project that combines wind power generation with magnetic levitation technology. Unlike traditional turbines that rely on mechanical bearings, this design uses magnets to lift and stabilize the rotor.

This magnetic field minimizes friction, allowing the turbine to spin freely even in very low wind speeds. It can start generating power at just 1.5 meters per second and continue operating efficiently even in strong winds above 40 m/s.

To build it, you’ll start with the supporting frame and frame base to hold the structure. Magnets are placed between the rotor and the base to create the levitation effect.

The shaft and bearings are added to support vertical motion, while blades catch wind from all directions. The motor then converts the rotational energy into electricity.

Because there’s almost no contact between moving parts, energy loss is minimal, and the system lasts longer with less maintenance.

This project helps your team understand renewable energy design, frictionless mechanisms, and efficient power generation.

Materials needed:

- Magnets

- Blades

- Supporting frame

- Frame base

- Motor

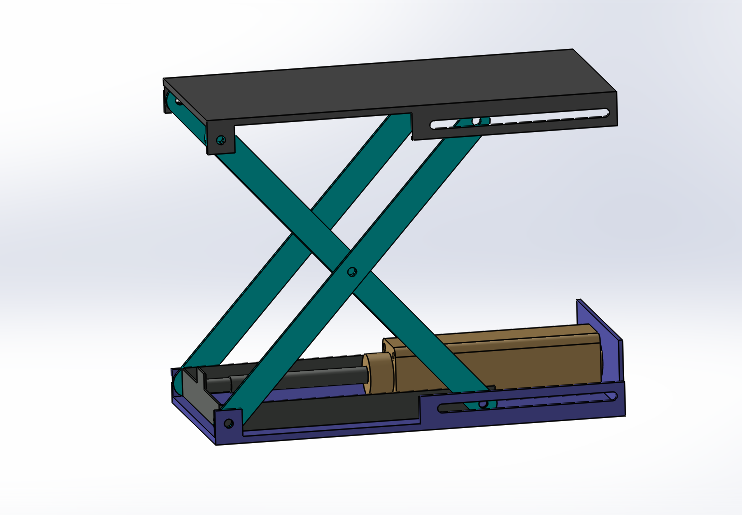

5. Pneumatic Scissor Lift Jack Project

Source: nevonprojects.com

The pneumatic scissor lift jack is designed to lift heavy loads using compressed air instead of manual force. It is an improved version of traditional screw or hydraulic jacks. Air pressure reduces the effort needed to lift a vehicle or other heavy objects.

The project works on a simple principle. When pressurized air enters the pneumatic actuator, it pushes the piston upward. This motion extends the scissor mechanism and lifts the platform or load from the ground.

When the air pressure is released, the piston moves downward, lowering the lift smoothly. This process removes the need for manual cranking and provides faster, safer lifting.

To build it, start by assembling the base frame and connecting rods that form the scissor structure. Attach the pneumatic actuator to the center point of the frame using mounts and joints.

Connect the pneumatic parts and fittings to supply compressed air. Finally, secure all parts with screws and fittings for stability.

This project helps your team understand pneumatic systems, mechanical linkages, and how air pressure can replace manual effort in lifting mechanisms.

Materials needed:

- Pneumatic actuator

- Pneumatic parts and fittings

- Connecting rods

- Base frame

- Mounts and joints

- Screws and fittings

Applications of Mechanical Design

Mechanical design is part of almost every product you use or see daily. From cars to smartphones, it shapes how things are built, how they work, and how long they last.

Let’s look at some industries where mechanical design is used:

Automotive Industry

In the automotive industry, machine design is used to develop engines, transmissions, and advanced suspension systems.

As electric vehicles become more common, engineers use new design methods to improve power efficiency and safety. They may study existing design models to improve battery cooling or reduce weight for better performance.

Every detail, from motor layout to frame structure, relies on precise mechanical planning and testing.

Aerospace

Mechanical design is key to creating safe, lightweight aircraft and spacecraft. Engineers use detailed modeling and research to make sure each part can handle extreme temperatures and pressure.

From jet engines to satellite mechanisms, adaptive design principles help improve efficiency and safety while keeping costs lower.

Book a demo today and explore how CADchat turns complex design collaboration into a simple process.

Medical Devices

The mechanical design field plays a huge role in developing medical devices. You see this in surgical robots, artificial limbs, and life-saving machines like pacemakers.

Each part must be small, durable, and reliable. Designers use research and design methods to make devices more precise and easier for medical staff to use.

Industrial Automation

In manufacturing and robotics, machine design helps build automated systems that improve speed and accuracy.

From robotic arms to conveyor systems, engineers use adaptive design to make machines that adjust to changing production needs. This approach cuts downtime and boosts output.

Collaborate Smarter During the Mechanical Design Process With CADchat

If your team works with CAD files, you know how hard it can be to keep communication clear and progress steady. Files get lost, feedback gets buried in emails, and version control quickly becomes a challenge.

CADchat changes that by bringing your entire product development design process into one shared space where engineers, designers, and stakeholders can work together in real time.

With CADchat, your product team can open 3D models together, leave comments directly on designs, and make updates instantly.

There is no need to export large files or wait for another design review meeting. It helps everyone, from engineers to non-technical teammates, stay aligned and move from concept to prototype faster.

Whether you are refining parts, testing assemblies, or reviewing final details before production, CADchat keeps your mechanical design collaboration organized and easy to follow. You spend less time managing versions and more time building great products.

Get started today and see how CADchat keeps mechanical design projects aligned from start to finish.

FAQs About Mechanical Design Examples

What are examples of mechanical designs?

Mechanical designs include machines, tools, and mechanical systems used in daily life, such as engines, pumps, and vehicles. They involve creating parts that move or work together to perform a task efficiently.

What are the three types of mechanical design?

The three types are product design, machine design, and system design. These different types focus on creating functional, safe, and efficient mechanical solutions that improve performance and support the use of modern technology.

What is a mechanical design?

A mechanical design is the process of planning and creating mechanical parts or systems that perform a specific function. It combines creativity and technical knowledge to turn ideas into working machines or equipment.

What are mechanical design jobs?

Mechanical design jobs involve designing, testing, and improving mechanical systems or products. People in these roles often work with engineers and manufacturers to turn technical plans into practical and efficient products.