Strong collaboration is a big part of effective supply chain management, especially during product development. But working with external suppliers, manufacturers, and logistics partners is not always easy.

In this article, we’ll talk about the common problems product teams face when working with supply chain partners, and explain how to easily solve them.

Why Is Effective Supply Chain Collaboration Important?

Supply chain collaboration means teaming up with suppliers, partners, and even customers to make the flow of goods and services smoother from beginning to end.

Now, let’s talk about why it’s so important to work closely with everyone involved in the supply chain.

Builds Stronger Supply Chain Responsiveness

When companies communicate clearly and work as a team, they can react faster to changes. That is what makes effective supply chain collaboration important.

Whether it is a delay, shortage, or shift in demand, quick action helps keep everything moving. This improves supply chain responsiveness and helps businesses stay on track.

Reduces Supply Chain Volatility

Good teamwork reduces risks. It helps all partners in supply chain operations spot problems early. That means fewer surprises and faster solutions.

With effective collaboration, teams can handle supply chain volatility better and keep operations stable even when the market changes.

Loop in your suppliers early and reduce last-minute changes. Try CADchat today.

Leads To More Efficient Resource Allocation

When partners share information and work closely together, they can save time, reduce costs, and use materials more wisely. This kind of teamwork helps everyone make smarter choices with the resources they have.

It also means fewer delays, fewer mistakes, and less waste. Every part of the process, from raw materials to final delivery, runs more smoothly and adds real value.

Improves Efficiency And Saves Costs

One of the top benefits of effective supply chain collaboration is improved efficiency. When tasks are coordinated, there is less waiting, fewer mistakes, and faster delivery. This cuts down costs and boosts profits without extra effort.

Enhances Customer Satisfaction

Faster delivery, fewer errors, and better service all help keep customers happy. With seamless integration across supply chain activities, businesses can meet demand without delay. That leads to repeat business and better reviews.

Supports Sustainability Initiatives

Working together also helps teams focus on reducing their environmental impact. By sharing goals around eco-friendly practices, supply chain partners can lower waste, use cleaner energy, and improve logistics.

These actions support long-term sustainability initiatives and show a company’s commitment to the planet.

Creates A Long-Term Competitive Advantage

Businesses that invest in supply chain collaboration efforts build stronger systems and deeper trust across partners. Over time, these efforts lead to smoother supply chain operations, better service for customers, and closer business relationships.

Together, these benefits give companies a clear edge over competitors who don’t work as closely with their supply chain partners.

Share 3D models with suppliers without sending email attachments. Use CADchat now.

9 Supply Chain Collaboration Challenges Your Team Should Know

Here are nine common problems your team should watch out for.

1. Lack of Trust

In product development, trust plays a big role in how well teams work together. When teams don’t trust each other, they avoid sharing key details like design files, testing data, or early feedback.

Engineers might hold back CAD files, and suppliers may be hesitant to share manufacturing limits. This slows things down and causes teams to repeat work or make decisions with missing information.

Without open communication, teams make guesses instead of working from the same facts. This leads to delays, design errors, and tension between partners. In the early stages of development, when changes happen fast, trust is even more important.

2. Communication Gaps

Clear communication is key in any supply chain, but gaps still happen. Teams might use different platforms, time zones, or even languages, which makes it harder to stay in sync. A simple misstep, like using the wrong version of a CAD file, can slow down an entire project.

When messages are unclear or don’t reach the right people, trust begins to break down. This is a big challenge in global supply chains where many teams must work together across borders.

Even with supplier collaboration tools in place, problems can still occur if those tools are not used correctly or consistently.

3. Conflicting Goals

External suppliers may often have goals that don’t fully match the goals of your internal team. While your team may focus on product performance, design features, or hitting a launch deadline, a supplier might aim to reduce production costs, simplify tooling, or shorten lead times.

These trade-offs often come up during the design review process, where each side pushes for what suits their own targets.

Make it easy for suppliers to review and comment on your CAD models. Contact us to learn more!

4. Poor Technology Integration

Many supply chains still rely on outdated or manual tools. Others use different platforms that don’t connect.

This causes slow data flow, more errors, and poor visibility across the process. Teams struggle to get the right information at the right time.

For example, if one partner uses advanced CAD software for mechanical engineers but another still relies on spreadsheets, it creates a gap. Sharing files, reviewing designs, and tracking changes become slow and messy.

5. Data Quality Issues

Good decisions depend on good data. When the data is wrong, missing, or inconsistent, it causes critical CAD issues that affect the whole project.

Product teams may order the wrong parts, miss deadlines, or base plans on bad information. This creates delays and extra costs. It also weakens trust between partners.

If one team sends out an outdated part list or the wrong inventory count, it can throw off the entire process. Mistakes like these are common when data comes from different sources and is not checked or updated often.

These issues hurt supply chain operations and slow down teamwork. Partners begin to doubt each other’s updates and stop relying on shared systems.

6. Resistance to Change

Change can feel uncomfortable. When new tools or processes are introduced, some employees may push back.

They might worry about losing control, making mistakes, or having more work. This resistance slows down efforts to improve collaboration.

Even if the change is helpful, like adopting faster software or a new workflow, people may still prefer the old way of doing things.

They feel safer with what they already know. As a result, progress stalls, and teams miss out on better ways to work together.

Improve your product quality by collaborating with suppliers earlier. Get CADchat now.

7. Lack of Visibility and Transparency

When systems and data are scattered, teams can’t see the full picture. They may not know where parts are, what’s in stock, or if shipments are delayed.

This lack of visibility makes it hard to plan, solve problems, or work together. It also slows down decision-making and weakens trust between partners.

Different formats, tools, and workflows across teams make it even harder to share updates. Without a clear view of inventory, production, and logistics, teams often rely on guesswork.

This lack of CAD interoperability leads to mistakes, missed deadlines, and extra costs.

8. Inefficiencies From Disjointed Processes

Disjointed workflows also make it harder to respond to changes or spot problems early. Your team may spend more time fixing issues than moving forward.

In product development, this often shows up when external suppliers follow different processes or systems. For example, your team might update a design, but the supplier continues working from an older file.

Or a change in material spec gets missed because there’s no clear way to share updates in real time. These gaps create delays, rework, and frustration on both sides.

9. Risk Management and Compliance Challenges

Product development often involves complex rules and strict quality standards. When external suppliers use different processes or follow their own compliance practices, small gaps can turn into big risks.

These might include missing test data, using non-compliant materials, or skipping required documentation.

Such issues don’t just delay the project. They can lead to failed audits, product recalls, or lost certifications. They also damage the working relationship between your team and the supplier.

Bring clarity to supplier feedback and keep it connected to your designs. Let CADchat help you.

Steps You Can Take to Overcome Supply Chain Collaboration Challenges

Improving supplier collaboration during product development takes planning, the right tools, and ongoing effort.

Here are some steps to help strengthen these partnerships and avoid common problems:

Align On Shared Goals Early

Before the project begins, work with your logistics partners and suppliers to define what success looks like. Align on cost targets, timelines, and quality expectations.

This makes it easier to resolve conflicts and helps everyone stay focused on the same outcome throughout the development process.

Invest In The Right Tools

Use tools that support real-time data collection, shared file access, and project tracking. When teams can see updates and stay connected, it’s easier to prevent errors, manage changes, and improve teamwork across locations.

Use Advanced Data Analytics

Machine learning and advanced data analytics help you spot risks early. By analyzing supplier performance, delays, or cost changes, you can make smarter decisions and keep the development timeline on track.

Improve Communication Standards

Set clear rules for how and when teams communicate. Use shared platforms, standard file formats, and routine check-ins to keep suppliers in sync with your internal teams. Good communication helps reduce confusion and delays.

Standardize Compliance Checks

Make compliance part of the workflow. Create checklists and shared guidelines that cover regulatory requirements and fair labor practices. This helps suppliers meet expectations and lowers the risk of quality or legal issues.

Explore Technological Advancements

Look into new tools that improve coordination, track progress in real time, and automate tasks. These technologies can enhance efficiency, make development smoother, and reduce costs by cutting down on delays and manual work.

How CADchat Enhances Collaboration Between Teams And Their Suppliers

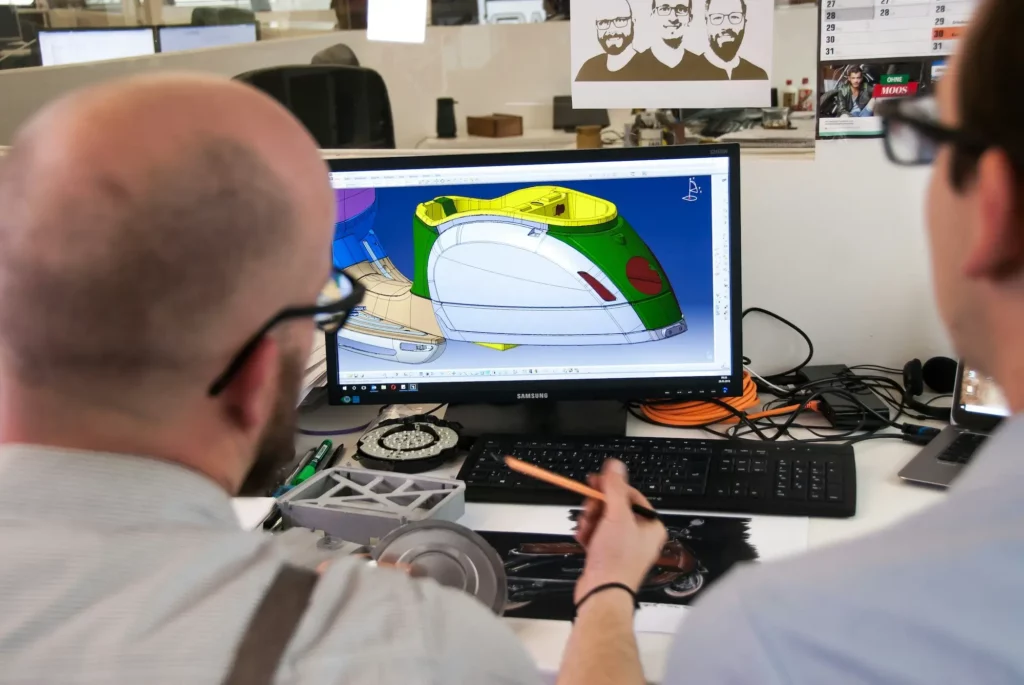

CADchat is a cloud-based meeting and collaboration tool made for teams that work with CAD files. It helps designers, engineers, manufacturers, and non-technical teammates work together without confusion.

CADchat makes it easy to meet live or leave feedback anytime, all inside one shared digital workspace.

It works with all major CAD file formats, so your team always works on the latest version. Whether you’re meeting live or working async, CADchat keeps everyone in sync.

- Real-time collaboration without screen sharing: Open and review CAD models directly in your browser. No need for file conversions or extra tools. Everyone can view, edit, and give feedback in one place.

- Instant input from manufacturers: Suppliers and machinists can flag issues and give feedback right on the model, helping teams fix problems early and avoid rework.

- Clear feedback from non-CAD users: Executives, marketers, and supply chain teams can review designs and leave comments without needing CAD software.

- Always work on the latest file: CADchat tracks all changes and versions, so teams never worry about using outdated files or missing updates.

- Async comments that keep work moving: Team members can leave comments anytime. Others can review and reply when available, so progress continues even without meetings.

Give suppliers exactly what they need to move faster. Start reviewing in CADchat.

FAQs About Supply Chain Collaboration Challenges

What are the obstacles to achieving supply chain coordination?

One of the biggest supply chain collaboration challenges is the lack of real-time data sharing and transparent communication between supply chain partners.

Without clear visibility into production schedules, inventory levels, or demand forecasts, it’s hard to create seamless coordination.

Inconsistent data, different goals, and limited use of supply chain collaboration software also make it tough to align supply chain processes and improve supply chain performance.

How to improve supply chain collaboration?

To improve supply chain collaboration, supply chain managers need to build stronger relationships with internal departments and external partners.

Using tools like supply chain collaboration software helps with real-time data sharing, better demand planning, and joint business planning.

Open communication, enhanced supply chain visibility, and aligned goals lead to optimized inventory management, reduced operational costs, and better overall supply chain performance.

What are the obstacles to supply chain integration?

The main challenges to supply chain integration include outdated systems, a lack of seamless data sharing, and misaligned supply chain strategies between trading partners.

Complex supply chains across global networks make integration even harder, especially without collaborative supply chain platforms or shared metrics.

These issues limit supply chain efficiency and hurt efforts to build a more resilient and responsive supply chain.

Why is supply chain collaboration still a hot topic?

Supply chain collaboration is still a hot topic because supply chain disruptions, cost reduction pressure, and rising customer expectations continue to grow.

Businesses are focused on enhancing supply chain resilience, boosting operational efficiency, and improving customer satisfaction.

Modern supply chains rely on advanced technologies and data analytics to strengthen collaborative relationships and stay competitive in the connected supply chain network.