Bringing a product from concept to market takes more than just good design work. It requires coordination between engineers, suppliers, manufacturers, and even non-technical stakeholders to overcome common supply chain collaboration challenges.

This is where supply chain collaboration comes in. By working together in a structured and transparent way, companies can reduce delays, improve efficiency, and meet customer needs more effectively.

Let’s look at what supply chain collaboration is, why it’s important in product development, and how teams can make it better.

Introduction to Supply Chain Collaboration

Supply chain collaboration is when companies and teams work together to manage the flow of goods, services, and information.

Each group doesn’t just focus on its own tasks; they work together. Supply chain partners share data, align on goals, and make decisions that benefit the entire chain.

This approach to supply chain management helps prevent delays, reduces wasted effort, and creates a more reliable system overall.

True collaboration means breaking down walls inside a business and also building trust with outside suppliers and partners. It shifts the focus from individual performance to shared success.

Modern collaboration tools and software support this by giving teams real-time access to information, so they can respond quickly when demand changes or problems come up.

The result is a supply chain network that runs more smoothly, saves money, and delivers better service to customers.

Companies that invest in improving collaboration within their supply chain operations often find that it improves both efficiency and relationships across the board.

Types of Supply Chain Collaboration

Collaboration in the supply chain can take different forms depending on the relationship between teams, departments, and companies.

Each type contributes to supply chain efficiency in a unique way, whether by improving communication, cutting costs, or driving innovation

Vertical Collaboration

Vertical collaboration happens when companies at different points in the chain work side by side.

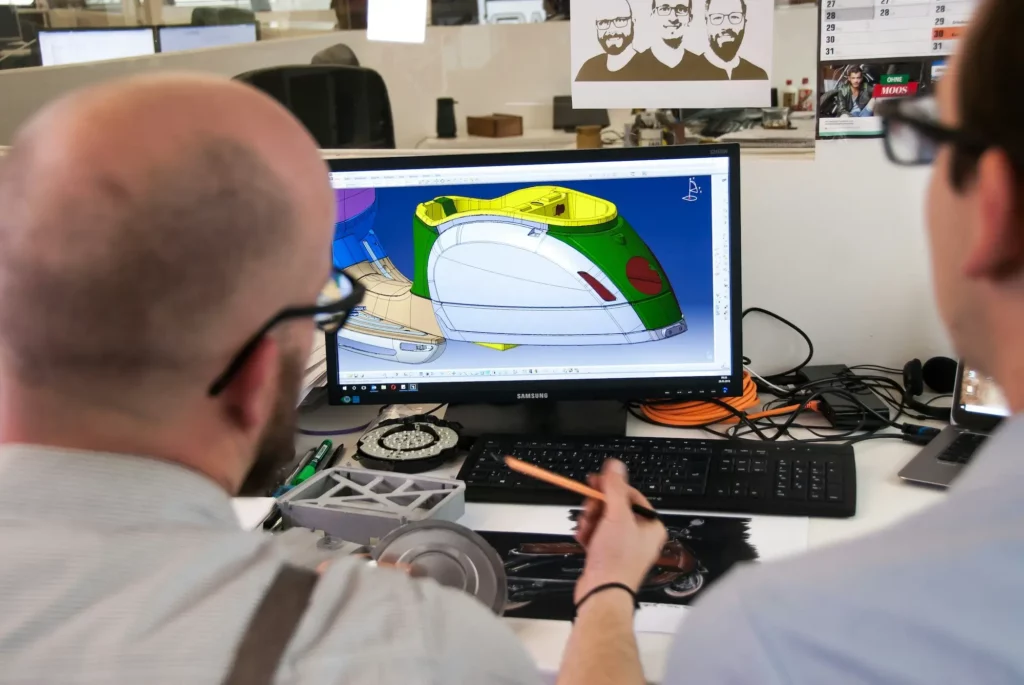

Manufacturers or design teams work closely with a materials supplier to plan for upcoming launches through design collaboration tools. By sharing demand forecasts and design updates, both sides can stay aligned and avoid delays.

For example, a smartphone company might involve its display supplier early in the design stage, so production capacity is ready when the product is released.

This type of teamwork not only improves supply chain performance but also sparks both incremental and radical innovation, since suppliers often bring new ideas and technology into the mix.

Horizontal Collaboration

Horizontal collaboration happens when they work with other companies at the same stage of the supply chain.

Teams may collaborate on model reviews, align on design standards, or exchange testing data to move projects forward more smoothly.

Take two design teams in the consumer electronics field. By agreeing to use the same CAD file formats, they make it easier for suppliers and prototyping partners to handle their models without extra conversions.

This reduces errors that often occur when working with disparate systems and keeps the product development process on track.

Even if the companies are competitors, this type of collaboration can benefit both sides. By pooling design knowledge or sharing early research, teams lower development costs, respond faster to challenges, and improve supply chain efficiency.

Internal Collaboration

Internal collaboration is about how well teams inside the same company connect. In product development, design, engineering, procurement, and logistics all need to stay in sync. If they don’t, delays and costly mistakes are almost certain.

Using shared platforms like enterprise resourcing (ERP) systems, supply chain management (SCM) systems, and other internal collaboration tools helps everyone access the same data and track progress in real time.

Think of a car company where the design team makes a small change to its design. If procurement and manufacturing see that update right away, they can adjust before production starts.

External Collaboration

External collaboration often means working closely with suppliers during the product development stage.

Suppliers bring knowledge that design teams might not have in-house, such as expertise in materials, machining, or tooling.

Sharing CAD models with suppliers using design review software gives them the chance to review designs early, suggest improvements, and highlight potential production challenges.

For example, a supplier might notice that a CAD design could be adjusted to reduce waste in manufacturing or speed up assembly.

Stop waiting for supplier reviews. Get started with CADchat now and keep projects moving forward.

Why Is Supply Chain Collaboration Important?

Strong collaboration across the supply chain is all about creating a collaborative environment where trading partners, suppliers, and internal teams share objectives and connect disparate systems.

Let’s look at the main benefits of supply chain collaboration efforts.

Assurance of Supply

When design teams release CAD models for new parts, suppliers need to know what materials and tooling are required. Sharing this information early gives suppliers time to prepare, reducing the risk of shortages.

For example, if an automotive team is developing a new component, sending 3D CAD files to material suppliers allows them to evaluate feasibility and secure resources before mass production starts.

This leads to fewer stockouts, smoother inventory management, and better customer satisfaction once the product launches.

Greater Efficiency

Effective collaboration reduces wasted effort across the supply chain. CAD models serve as a single source of information that suppliers, engineers, and manufacturers can all reference.

Instead of duplicating work, partners work from the same design data, which reduces errors and accelerates the supply chain process.

When a consumer electronics company shares its CAD files with mold makers and assembly teams, adjustments can be made quickly, reducing rework and cutting operational costs. This type of cross-functional collaboration supports both speed and operational efficiency.

Improved Responsiveness

Supply chain disruptions are unavoidable, but how companies respond makes all the difference. A connected supply chain allows teams to share real-time data and adapt together. Take the case of a sudden shortage of a key material.

With strong collaboration, procurement teams, logistics providers, and manufacturers can coordinate a new plan quickly, whether that means finding alternate suppliers or adjusting production schedules.

This responsiveness helps keep operations steady and prevents long delays in the supply chain process.

Innovation and Growth

Working together often sparks new ideas that fuel innovation. Companies in the same industry might collaborate on research and development to lower costs and spread risk.

For example, two medical device makers could partner with a materials supplier to create safer, more advanced components. This type of cross-functional collaboration encourages both incremental and radical innovation.

It also opens doors to new markets, since shared knowledge and resources make it easier to test and launch products that meet customer needs.

Risk Management

Every supply chain faces risk, whether from natural disasters, supplier failures, or economic shifts.

Collaboration helps spread this risk across trading partners. By building shared contingency plans, businesses create resilience.

A manufacturer and its logistics provider might agree on backup transportation routes in case of border delays during a design review meeting.

These joint strategies reduce the impact of disruptions and improve stability across the supply chain. Over time, these practices support continuous improvement and create a stronger, more reliable network.

Long-Term Partnerships

Short-term transactions do not build stability. Long-term relationships with external partners, however, create trust and mutual benefits.

When product teams collaborate closely with suppliers, distributors, and logistics providers, they gain more favorable contract terms, better service levels, and stronger decision-making support.

These relationships also encourage continuous improvement, since both sides are invested in long-term success.

Cost Savings

Collaboration has a direct impact on cost reduction. Shared transportation, joint procurement, and consolidated warehousing are practical ways to cut expenses.

Two companies might combine their shipments to reduce freight costs and lower their environmental impact at the same time.

By connecting disparate systems and aligning on shared objectives, businesses avoid unnecessary spending and improve overall operational efficiency.

These savings can then be redirected into product development, research, or new customer-focused initiatives.

Start with CADchat now and let suppliers give real-time feedback without slowing your cycle down.

Tips on How to Improve Supply Chain Collaboration

Building a collaborative supply chain takes more than good intentions. Here are practical ways companies can improve supply chain collaboration.

Promote Transparent Communication

Successful collaboration starts with open and consistent communication. Design teams, procurement teams, and logistics partners need visibility into the same information at the same time.

Sharing updates on production schedules and procurement processes avoids surprises and keeps everyone aligned.

Regular check-ins and digital platforms make it easier to maintain this level of transparency.

Strengthen Supplier Collaboration

Involving suppliers early in the design phase leads to better outcomes. Sharing CAD models and specifications allows suppliers to point out challenges before production begins.

This type of supplier collaboration improves material choices, reduces waste, and keeps production schedules realistic.

It also helps suppliers prepare their own operations, creating a smoother flow across the supply chain.

Use Real-Time Data Analytics

Real-time data analytics helps teams make informed decisions quickly.

When internal departments and external partners access live data, they can track inventory levels, monitor logistics, and adjust production schedules without delay.

Analytics also highlight patterns that improve procurement processes and help measure success using key performance indicators.

Encourage Joint Decision-Making

Collaboration works best when decisions are made together.

Whether it is planning procurement strategies, setting production schedules, or coordinating with logistics partners, joint decision-making aligns everyone on shared goals.

This reduces conflicts, balances priorities, and creates a more successful collaboration across the supply chain.

Measure Success With Clear KPIs

To know if collaboration is working, companies need to measure success. Setting clear key performance indicators, such as lead times, cost savings, or on-time deliveries, helps track progress.

Reviewing these metrics regularly allows teams to refine processes and keep improving the collaborative supply chain.

Apply Both Horizontal and Vertical Collaboration

Improvement comes from working across levels and within the same level of the supply chain. Horizontal and vertical collaboration together create stronger results.

For example, horizontal collaboration might involve companies sharing logistics resources, while vertical collaboration focuses on aligning suppliers and manufacturers.

Combining both approaches helps reduce costs, speed up processes, and support innovation.

Advanced Collaboration Practices You Can Try

As supply chains grow more complex, traditional methods of coordination are no longer enough.

Companies are turning to advanced collaboration practices that combine technology, data sharing, and closer partnerships.

These approaches help improve supply chain performance, reduce costs, and make operations more resilient.

Here are three strategies design teams and their partners can put into practice.

Collaborative Planning, Forecasting, and Replenishment (CPFR)

CPFR is a framework where companies share demand forecasts, sales data, and inventory details to stay aligned.

For design and product development teams, this means suppliers and retailers gain early visibility into demand for new products.

When forecasts are accurate, production schedules can be better aligned with customer demand, reducing both stockouts and excess inventory. CPFR also fosters trust, since partners are more transparent with data.

A stronger relationship between suppliers and retailers improves responsiveness, making it easier to adjust when market conditions shift.

Vendor-Managed Inventory (VMI)

With VMI, suppliers take responsibility for monitoring and replenishing inventory at the customer’s site.

Real-time data and analytics make this possible, giving suppliers direct insight into stock levels.

This reduces the burden on retailers or manufacturers who would otherwise track every part themselves. VMI helps optimize inventory, reduce carrying costs, and improve service levels.

For example, a supplier managing components for a new consumer electronics launch can keep stock flowing smoothly without waiting for repeated purchase orders. This leads to a more efficient and reliable supply chain process.

Collaborative Transportation Management (CTM)

Transportation is one of the most resource-heavy parts of the supply chain, and CTM helps reduce that burden.

In CTM, manufacturers, suppliers, distributors, and logistics partners share resources to optimize shipping. This might mean consolidating shipments, sharing freight capacity, or using digital platforms to track routes in real time.

CTM is especially valuable when prototypes or new product batches need to move quickly between facilities.

By pooling transportation resources, companies cut costs, reduce empty miles, and lower carbon emissions, all while improving delivery reliability.

How Collaboration Software Helps Your Supply Chain

Supply chain collaboration software makes it easier for teams and partners to work together in a collaborative manner. By bringing in advanced technologies, it connects people, processes, and data so everyone stays on the same page.

Here’s how the right tools can make a real difference:

- Seamless communication: Software gives internal teams and suppliers a single place to share updates. Through supplier portals, everyone can see production schedules and inventory levels in real time, which helps cut down on delays and keeps projects moving.

- Collaborative forecasting: With access to shared data, design teams and logistics partners can plan ahead together. This means better forecasting, fewer shortages, and a quicker response to changing market demands.

- Strategic alignment: Collaboration tools link different business functions like procurement, production, and sales. When these groups are aligned, it’s easier to improve efficiency and support effective supply chain collaboration.

- Fostering strong partnerships: Sharing data openly builds trust with suppliers and logistics partners. Over time, this creates stronger relationships that make the supply chain more flexible and reliable.

- Improve efficiency: Software helps cut down on waste and reduce operational costs by automating processes and providing real-time data analytics. This makes it easier to adapt in a competitive environment while keeping up with customer demands.

- Increased customer satisfaction: When operations run smoothly and products arrive on time, customers notice. Meeting expectations consistently leads to greater loyalty and stronger trust in the brand.

Power Supply Chain Collaboration With CADchat

Supply chain success in product development depends on more than good communication. It requires operational performance, process automation, and integrating processes across every partner.

CADchat gives engineers, designers, manufacturers, and suppliers one shared space to collaborate directly on CAD files, helping teams move faster with fewer mistakes.

Here’s how CADchat makes collaboration easier and smarter:

- Boost operational performance: Real-time CAD reviews cut down on delays, reduce rework, and speed up approvals.

- Simplify process automation: Supplier portals and threaded feedback keep updates organized so nothing gets lost.

- Integrate processes across partners: Internal teams and external suppliers stay aligned on production schedules and design updates in one place.

The result is a collaborative supply chain that delivers faster decisions, stronger supplier relationships, and products that reach the market without costly holdups.

FAQs About What Is Supply Chain Collaboration

What is an example of a supply chain collaboration strategy?

An example is when suppliers and retailers share sales and inventory data so they can plan stock levels together. This helps streamline operations, reduce shortages, and cut waste, making the process smoother for both sides.

What is the main objective of supply chain collaboration?

The main goal is to create better coordination between partners so products move faster and more accurately through the chain. By working closely with internal stakeholders, companies can lower costs and improve customer satisfaction.

What is supply chain collaboration in Ariba?

In Ariba, supply chain collaboration means suppliers and buyers use the same digital platform to manage orders, invoices, and shipping details. This setup improves visibility, speeds up responses, and makes the process more reliable.

What is CPFR in the supply chain?

CPFR, or collaborative planning, forecasting, and replenishment, is a method where suppliers and retailers plan demand and restocking together. This approach helps reduce errors in forecasts, prevents overstocking, and supports smoother supply chain flow.