Workflows can get messy fast for product teams. Tasks pile up, designs move in different directions, and feedback gets lost across emails, chats, and scattered tools.

Engineers wait for missing details. Designers update the wrong file. Stakeholders jump in late and question decisions that have already been made.

When each team follows a different process, even simple decisions take longer than they should. Clear workflows change that. When a team knows how work moves, who owns each step, and where decisions live, everything becomes easier to track and faster to deliver.

In this article, we’ll walk you through engineering workflow stages and strategies product teams use today.

How an Engineering Workflow Works

An engineering workflow is a set of steps that an engineering team follows to move a project from the first idea to a final release. It gives the team a clear path, so work moves in the right order. The flow usually covers planning, design, development, testing, and review.

A good workflow supports steady progress across each stage. It also helps the team keep designs organized as they move between a staging environment and a production environment. This creates a smooth transition when the work is ready to go live.

Many teams use continuous integration to check new changes often. This reduces surprises later and keeps the project stable as more pieces come together.

Different workflows fit different situations. Some follow strict steps while others stay flexible to match the project’s specific needs.

No matter the method, the goal stays the same: to have a clear workflow that builds efficiency and supports steady, high-quality work.

Engineering Workflow Stages

An engineering workflow moves through clear stages that help the team stay organized from the first idea to the final handoff.

Stage #1: Planning

The planning stage builds the foundation for the entire project. This is where the team slows down and defines what they want to achieve before any CAD work begins.

They review goals, limits, risks, and the exact problem the product must solve. This includes studying user needs, checking what similar products do, and collecting early constraints such as size, cost, and materials.

The team also chooses the tools they will use, including CAD software, testing equipment, and manufacturing partners.

Planning often involves basic feasibility checks. Engineers look at whether the idea is realistic with the chosen materials, production methods, and budget. They may create rough timelines so the team knows when key work should happen.

Stage #2: Design

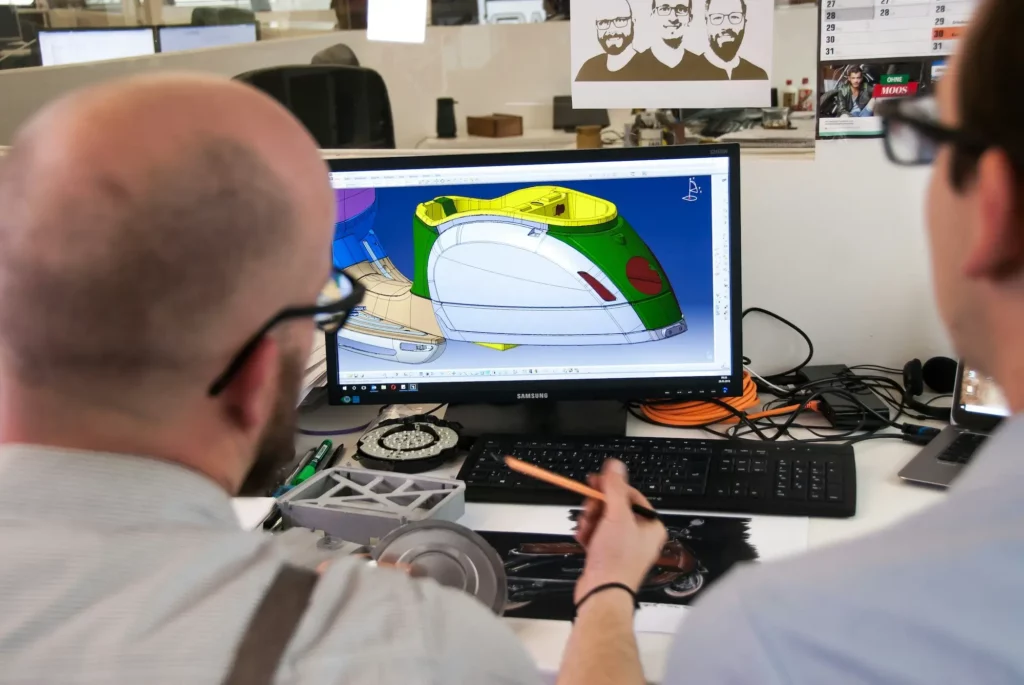

In this stage, engineers turn early ideas into clear, detailed CAD work. They use CAD software to build models, create drawings, and shape early prototypes that show how the product will look and function.

These models help the team understand form, fit, and movement before anything is built in the real world.

Engineers check how parts fit together, test clearances, and adjust geometry to avoid collisions or tight spots.

Design reviews happen often. The team compares concepts, assesses trade-offs, and checks whether the choices align with the project’s needs. They may explore several versions of a part to see which option works best for cost, strength, or ease of assembly.

Stage #3: Development

The development stage is where the design turns into something real. The team takes the approved CAD models and begins building the actual parts.

This can include detailed modeling for final geometry, machining metal components, printing early versions with additive manufacturing, or assembling sub-systems to check fit and function.

Engineers often refine tolerances, adjust features for manufacturability, and confirm that each part performs as expected when combined with others. They may prepare multiple iterations, starting with rough prototype builds and moving toward near-final versions.

This stage also includes creating fabrication drawings, choosing materials, and collaborating with suppliers or vendors who will produce the parts.

Stage #4: Testing

In the testing stage, the team confirms that the product performs the way the design intended. This is where digital work and physical results meet.

Engineers check function, quality, and performance to make sure the product behaves correctly before it reaches real users.

Testing begins with tolerance checks to see if manufactured parts match the project dimensions. Even small changes can affect fit or movement, so the team measures key features with care.

Material tests follow. These show how parts handle load, wear, heat, or impact, which helps the team spot weaknesses that were not visible in early designs.

Assembly trials give the team a clear view of how all parts work together. They build early prototypes to find tight clearances, alignment issues, or assembly steps that take too much time. When something does not look right, the CAD model is updated and tested again.

Stage #5: Deployment

The deployment stage is where the product leaves the engineering space and enters real use.

This shift can happen on a production line, in a customer test site, or in a controlled staging environment where the team can monitor performance closely. The goal is to confirm that the product functions as expected outside the design and prototype phases.

Engineers prepare clear instructions that guide assembly, handling, and operation. These instructions often come from lessons learned during earlier testing and prototype builds.

The team also sets up tools, fixtures, and equipment needed to support smooth production or field testing. If the product has multiple parts or sub-assemblies, they check that each step is easy to follow and free from hidden issues.

During deployment, engineers watch how the product behaves under real conditions. They pay attention to stress points, movement, wear, and user handling.

They may run small pilot batches or limited field runs to collect early feedback. Any issues found here turn into updates for the CAD model or process notes for production.

Stage #6: Monitoring and Control

In this stage, the team keeps a close watch on how the product performs as it moves through real use, testing, or early production.

They track progress against the plan and check whether each part behaves the way the design intended. This can include measuring tolerances, reviewing how parts wear over time, checking how assemblies handle load, or observing how the product reacts under real working conditions.

The team also looks for small issues that could grow into bigger CAD problems. These may be minor alignment shifts, unexpected friction, slow assembly steps, or material behavior that differs from early tests.

Stage #7: Closure

The closure stage wraps up the entire project and makes sure nothing is left unfinished. The team brings all work together, completes the final documentation, and prepares the product for long-term use.

This includes organizing CAD files, updating drawings with final dimensions, storing manufacturing notes, and saving the latest approved models in the correct locations. Good file hygiene matters here because future teams will rely on this information.

Engineers also create clear reports that explain what was built, why certain decisions were made, and how the final product performed in testing.

These reports help stakeholders understand the end result and give future engineers a strong reference when they work on updates or new versions.

The team hands off the product to the group that will use or support it, such as manufacturing, operations, or a customer team.

During this handoff, they walk through key features, assembly steps, and important notes that help others work with the product smoothly.

4 Engineering Workflow Strategies You Can Try Out

Engineering workflow strategies help engineering teams and project managers move from early ideas to finished work in a clear and steady way.

They bring structure to project management through careful planning, simple steps, and clear ownership. This helps teams avoid confusion and stay aligned.

Here are four simple workflow strategies you can try to bring more clarity, speed, and alignment to your product development process.

1. Agile Engineering Workflow Management

Agile workflow management is a way of guiding work through a clear and flexible structure that supports steady progress.

It uses an iterative approach, which means teams build small parts of the product, review them, and make adjustments as they learn. This helps everyone stay aligned and reduces confusion as the project moves forward.

Commonly used in software development and data engineering workflows, this approach also works well with product development because it helps teams act fast, spot gaps early, and shift when needed.

Each step leads into the next, so the entire process stays easy to follow. Team members plan goals together, set priorities, and keep the work visible so no one feels lost.

Agile Engineering Workflow Strategy in Product Development

The agile engineering workflow strategy follows a clear flow that helps teams move through the product development process. Here’s how it works:

- Vision and backlog creation: The team sets a clear product vision and turns broad goals into a prioritized backlog of CAD tasks, features, and engineering work.

- Sprint planning and team commitment: The team selects the CAD work and design tasks they can finish in a two to four-week sprint, breaking them into clear, manageable steps.

- Iterative development and continuous integration: The team produces small, usable updates such as new CAD features, revised parts, or early prototypes.

- Ongoing testing and quality assurance: Testing happens throughout the sprint, including fit checks, tolerance checks, material reviews, and simple prototype validation.

- Sprint review and customer feedback: The team presents updated CAD models or prototypes to stakeholders and gathers feedback to guide the next sprint.

- Sprint retrospective and process improvement: The team reflects on collaboration, tools, and workflow, then applies small improvements.

- Release and incremental deployment: Approved updates move into the staging or production environment, such as updated drawings, prototype runs, or pre-production builds.

How Agile Workflows Help Product Teams

Agile workflows help product teams move through the engineering process with steady progress. The method keeps work simple, clear, and flexible so the team can react fast without losing direction.

Each stage becomes easier to manage because the team works in small steps, gathers feedback often, and adjusts before CAD problems grow.

An agile workflow also saves valuable time by breaking big work into smaller tasks that the team can finish and review quickly. This makes it easier for designers and engineers to get a design approved because it gives them more room to refine and improve the product.

Frequent check-ins support quick identification of issues, which protects the team from spending too many resources on work that will change later.

The workflow also strengthens the team’s ability to collaborate. Designers, engineers, and manufacturers get access to the same information, which makes handoffs smoother and reduces confusion.

Want smoother collaboration in product design? Contact sales today and see how CADchat helps.

2. Scrum-Based Workflow Strategy

A scrum-based workflow strategy is a specific strategy within the agile framework. It uses short cycles called sprints, usually one to four weeks long, to keep project progress visible and easy to track.

The method relies on defined roles like scrum master, product owner, and engineers, which keeps ownership clear throughout the project.

Work is organized in a product backlog where the team breaks large tasks into smaller ones that are easy to plan and act on.

Sprint planning sets the goals for the cycle, daily stand-ups keep everyone aware of the project status, and reviews help the team check results with real users. These moments make room for user feedback so the product grows in a direction that matches real needs.

This workflow strategy keeps the product development process clear, adaptable, and able to handle complex work without losing focus.

Scrum-Based Workflow Strategy in Product Development

Scrum works well for product engineering teams that deal with complex CAD models and frequent design changes. Let’s see how it works:

- Assemble the scrum team: The team includes a product owner who sets priorities, a scrum master who guides the process, and engineers and designers who carry out the work. Product managers may help refine goals and keep plans clear.

- Create and refine the product backlog: The product owner builds and updates a list of user stories or tasks. The backlog stays organized so the team can select the right work each sprint.

- Plan the sprint: The team chooses the top items for the next one to four-week sprint. They set a clear goal and break the work into small tasks that the team can complete together.

- Execute the sprint and sync daily: The group works through the tasks and uses short daily engineering stand-ups to talk about progress, blockers, and tool issues that need quick attention.

- Review and reflect: Completed work is shown to stakeholders for feedback. The team then holds a retrospective to note what worked well and what to improve in the next cycle.

How Scrum-Based Workflows Help Product Teams

Scrum-based workflows help product teams move faster and stay aligned through steady communication and clear roles.

Short sprints give the team a simple way to react to changing design needs, client input, or technical issues without slowing the project down. This steady rhythm helps prevent data silos because everyone works from the same backlog and shares updates often.

Daily stand-ups and sprint reviews also keep stakeholders informed and give the team a chance to identify human error and other possible problems early.

Each sprint delivers a usable update, which helps teams test ideas, refine designs, and shorten the path to working prototypes.

Scrum also supports better teamwork. Cross-functional members share insight on 3D rendering, modeling, testing, and data pipelines so the group can find issues early and avoid rework.

Retrospectives add another layer of learning, helping the team adjust tools, communication, and workflow steps in simple ways.

3. Kanban-Based Workflow Management

Kanban-based workflow management is a simple and visual way for product engineering teams to track work as it moves through clear stages.

A Kanban board shows each step of the process, and tasks appear as cards that shift from left to right as the team completes them.

The method adapts well to teams working on shared tasks, such as product development.

Cards make ownership clear, and everyone can see the same board, which helps the group avoid taking on too much at once.

Kanban-Based Workflow Management in Product Development

Kanban gives product teams a simple way to track work without overload. Let’s see how it works in product development:

- Visualize the work: The team places product development tasks on a shared board so everyone can see progress at a glance.

- Limit work in progress (WIP): The team sets limits for each stage so the group does not overload itself. Fewer active tasks lead to better focus and higher product quality.

- Manage the flow: Tasks move through the board as the product evolves. The team watches cycle times and removes blockers to keep development steady.

- Stay flexible as priorities shift: New ideas or changes can be added without disrupting the system.

- Review and improve: The group reviews results often and updates the workflow based on what they learn. Simple automation can help with tracking or handoffs, making implementing improvements easier.

Book your demo now and see how CADchat helps teams focus on creating, not chasing feedback.

How Kanban-Based Workflows Help Product Teams

Kanban supports product teams by giving them a clear view of the work and a steady flow that keeps projects moving without unnecessary delays.

The visual board makes every task easy to track, which helps teams monitor project health and gather early feedback before issues grow.

Kanban also improves performance because limiting active tasks reduces context switching and helps the team finish work faster. With fewer items in progress, the team can focus on the tasks that matter most, leading to better outcomes and clearer ownership.

The method also gives product teams valuable insights into how work moves through each stage. Metrics like cycle time and throughput reveal slow spots and help the team improve the workflow over time. These insights support better planning and more confident decisions.

Kanban’s flexible structure also lets teams respond quickly when priorities shift or new requirements appear.

4. Lean Workflow Strategy

A lean workflow strategy is built on five core principles: identifying value, mapping the value stream, creating flow, establishing a pull system, and pursuing perfection.

The goal of this workflow strategy is to keep tasks simple, reduce delays, and help teams move through the design process with clarity.

Lean teams look closely at every step, decide what matters most, and remove anything that slows progress. This creates a smoother path for developing new features or improving existing work.

A lean strategy also supports continuous improvement, which means the team reviews the workflow often and makes small adjustments that help the process run better over time. These changes can come from team observations, user needs, or problems found during day-to-day work.

Lean Workflow Strategy in Product Development

Teams use lean principles to make sure every activity supports the final outcome and nothing extra gets in the way. Let’s see how it works:

- Identify customer value: The team defines what customers truly need and focuses on features and tasks that support that value.

- Map the value stream: The team visualizes every step in the development process. This helps them spot waste, delays, or work that does not add value so it can be removed or improved.

- Create a continuous flow: Work moves smoothly from one stage to the next. This helps engineering, design, and production teams stay aligned and reduces the chance of bottlenecks.

- Use a pull-based system: The team works on tasks driven by real demand or clear feedback rather than guesswork. This reduces extra work and keeps development focused.

- Pursue steady improvement: The team uses cycles of testing, feedback, and updates to refine the product. They start with a minimum viable product (MVP), the simplest version of a product that includes only the core features, allowing the team to learn quickly and adjust based on real user input.

How Lean Workflow Strategy Helps Product Teams

A lean workflow strategy helps product teams save significant time, stay focused, and eliminate tasks that do not support the final product.

The lean strategy also supports strong collaboration because every step in the product development process is visible. When teams map the value stream and remove waste, communication becomes clearer, and handoffs become easier.

Continuous flow and pull-based work help teams react quickly when priorities shift. They build only what is needed, which shortens development cycles and improves product quality.

Many teams describe the lean workflow strategy as a game-changer because it simplifies decision-making, removes bottlenecks, and supports ongoing learning.

Keep Your Engineering Team Aligned With CADchat

No matter which workflow a product team uses, CADchat makes the process easier to follow and much faster to complete. Agile, Scrum, Kanban, and Lean all rely on clear communication, steady feedback, and strong alignment.

CADchat is a meeting platform that gives teams a shared place to define goals, review designs, and keep discussions tied to the actual CAD model. This helps teams optimize their process from the first idea to final approval.

Teams can explore designs live, leave async notes, and review changes directly inside the model. This makes identifying risks or potential issues easier because everyone sees the same thing in real time.

Product teams can also track decisions and updates inside persistent workspaces, which pair naturally with version control and keep progress clear.

When sprints, flows, or iterations move quickly, CADchat helps teams set the right priority by connecting feedback to the exact part of the design that needs attention.

Make collaboration easy in your engineering workflows. Get started with CADchat today!

FAQs About Engineering Workflow

What are engineering workflows?

Engineering workflows are clear steps that guide a team in planning, building, testing, and shipping technical work. These steps help people stay on the same page and move tasks from start to finish in a steady way.

What are the five stages of workflow?

The five stages of a workflow often include planning the work, starting the task, checking progress, reviewing the output, and closing the task once it meets the goal.

Each stage helps the team keep work moving in a smooth and organized way. The flow stays simple, so everyone knows what comes next.

What are the seven steps of the engineering process?

The seven steps of the engineering process usually start with spotting a problem, learning more about it, thinking of ideas, picking the best approach, building a model, testing it, and making changes as needed.

What is a workflow engineer?

A workflow engineer is someone who looks at how work moves through a team and finds ways to make the steps clearer and easier to follow. They study how tasks flow, set up tools, and help teams work with fewer delays. Their focus is on making work feel simple and well-organized.